Solar power along the motorway

The Dutch road and railway network is flanked by some five million square meters of noise barriers. If we were to replace the bulk of those barriers by transparent colored Plexiglas we could generate a huge amount of green power. Before long test barriers will be put up near Den Bosch which will have to show whether that dream of TU/e researcher dr. Michael Debije, expert in the area of luminescent solar concentrators (LSCs), can ever become reality.

For many years Debije has tried to raise funds for a serious case study into the application of these alternative solar panels for the generation of energy in the public space. This pursuit has proved to be difficult: on the one hand because such a project comes exactly in the gap between chemistry and architecture, and on the other hand because the comparison with the successful silicon solar cells is soon made. “Under ideal circumstances the latter have a higher yield, it must be admitted”, says the American with Dutch ancestors. “However, that comparison won’t hold. You should compare the solar noise barriers with ordinary noise barriers. And the latter have a zero yield.”

Still, at last things are about to be realized: thanks to a subsidy from the Energy Top Sector, construction company Heijmans is going to put up two five-meter-wide-and-four-meter-high barriers along the west ring road of Den Bosch, made of orange and red semi-transparent sheets of PMMA (better known under the brand names of Plexiglas and Perspex). In addition to the alternative plastic solar panels of Debije, noise barriers with ‘conventional’ silicon cells will also be installed for the purpose of comparison.

In this so-called ‘Living Lab’, which has been given the name of ‘Solar Noise Barriers (SONOB)’, TU/e and Heijmans are involved as well as noise barrier manufacturer Van Campen Industries, space company Dutch Space and knowledge institutions ECN and SEAC. For the project, which is to begin early in 2015 and is to run for at least one year, TU/e will appoint a PDEng student in the Smart Energy Buildings & Cities program. This trainee design engineer will not only look at the energy yield of the barriers, but will also investigate the acceptance of road users and neighbors.

That acceptance is essential, as Debije explains: “Although silicon solar cells are profitable now, you still see them less than you would hope. This is due partly to their sensitivity to external influences, but also to the fact that not everybody thinks they look nice on their roofs.” So whether the solar noise barriers will be successful does not only depend on the (financial) yield. Parties involved, such as road managers, landscape architects, neighbors and road users must also accept them aesthetically in the landscape.

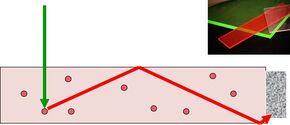

The American mentions as one big benefit of the new, modular solar noise barriers that they have been made of almost the same material as many current noise barriers. “Hardly any adjustments need to be made to the construction. You only need to install some electricity at the edges of the barriers and in the frame.” For it is only along the two-centimeter-thick edges of the barriers that strips of solar cells must be applied. The sunlight falling onto the barriers is caught by the fluorescent dye molecules in the plastic and converted into orange or red light, which is reflected to the edges of the solar concentrator.

That bundling of sunlight is expected to make the solar noise barriers relatively cheap, Debije explains. “The surface of solar cells required is a fraction of the total size of the barrier. It only costs a few euros for dye per five-by-four-meter barrier. Moreover, since light of a specific color is left, you can choose solar cells that produce a high yield at precisely that color.”

The solar noise barriers can stand hard wear

In addition, PMMA is a tried and tested construction material, which can stand hard wear. Splashing gravel, bird droppings, graffiti and shade are less of a problem for LSCs than for silicon cells. Indeed, when a small portion of a series of silicon cells is covered, this affects the yield of the whole series. “LSCs are far less sensitive to that. Of course you will catch less light when a barrier is sprayed with graffiti, but that effect is limited to just that spot. Besides, LSCs also work relatively well when they do not catch the sunlight at a right angle or when there is merely diffuse light, for instance on a cloudy day.”

Debije points at a piece of red Plexiglas in the corner of his study, fitted with cables and plugs. “Forty by sixty centimeters. That is about the size used in the laboratory for tests. It has not yet been shown anywhere whether larger sheets also work well, which is exactly why the field test conducted at present is so important.”

If the tests are successful, and the market is subsequently prepared to invest in solar noise barriers on a large scale, this will immediately bring various other applications within easy reach, Debije hopes. Then it will be profitable, for instance, to clad the walls of remote bus shelters with LSCs and thereby to generate enough power to illuminate the shelters at night. Or to do something for the Third World: “My original plan was to make LSCs to be used on roofs in Africa. The power generated in the daytime can be used at night to illuminate a room. You can also do that with silicon cells, but it has turned out that those often get stolen: they look too valuable. In the Netherlands, too, we have bad experiences with solar panels in remote areas, along lonely roads. They don’t last long in general.”

The principle of the luminescent solar concentrator has been known for decades, says Debije. “During the energy crisis in the 1970s a lot of research was conducted into LSCs, but once the oil price started going down again, this came to a virtual standstill.” And when the interest in solar power increased again in the 1990s, the silicon cells were the first to win the battle for then.

“Because of that previous history there are not so many groups worldwide working on LSCs at present, but in the Netherlands there is a lot of knowledge available, relatively speaking.” And Debije adds that a few groups abroad, including one at MIT, are also intending to put this technology on the market. “In the area of silicon cells China has beaten us. It would really be a pity if we also miss the boat here with LSCs.”

Discussion