Home Stretch | Aided by a robotic arm

The assistance of a robotic arm of sorts can be very welcome for people with a muscular disease. With this aim in mind, PhD candidate Bob van Ninhuijs designed an artificial 'shoulder joint' in which the use of magnets allows for energy-efficient compensation of gravity.

People who need to use a wheelchair due to a progressive muscle-wasting disease like Duchenne or ALS will at some stage lose the muscle strength needed to raise their own arms. This turns even simple actions, such as holding a glass of water, into insurmountable problems.

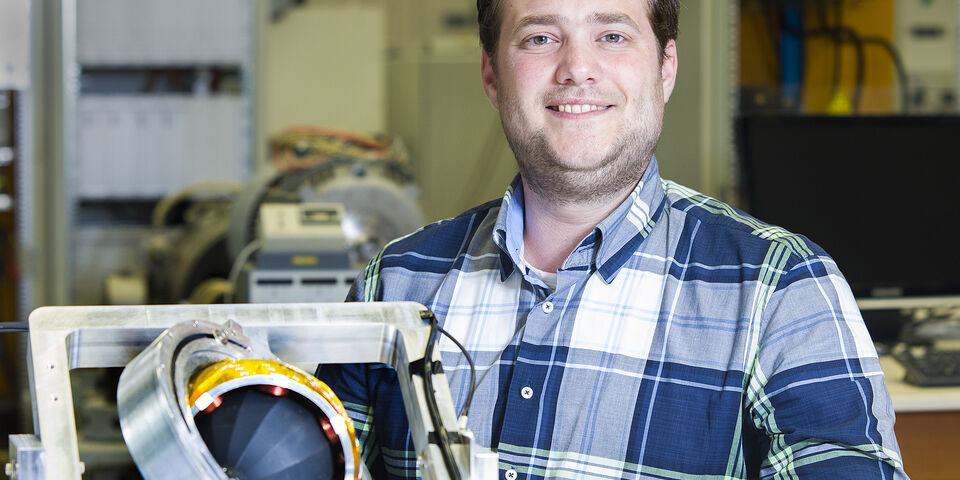

“With a moveable arm support, these people can regain some of their independence,” tells PhD candidate Bob van Ninhuijs in the lab of Electromechanics and Power Electronics. “As yet this support is powered by a mechanical spring that provides the power the individual can no longer generate. But at some point, as the muscles deteriorate further, this becomes insufficient.”

A sophisticated, electronically controlled robotic arm would offer a way forward for patients with an advanced muscle-wasting disease. Van Ninhuijs was tasked with creating some kind of shoulder joint for this robotic arm, a joint that would give the arm to which it is attached the necessary freedom of movement.

“The elbow too must be able to move, but that can be achieved with a regular electric motor,” he says. “Simulating a shoulder joint is a trickier proposition because it is a ball-and-socket joint. Moreover, much of the force generated by the arm is exerted on this joint; the main challenge was to make the joint strong enough yet also energy efficient, because you want to run the robotic arm off the wheelchair's battery, which is likely also running a respirator. That battery's power needs to last for at least a day.”

The unique design has been patented

Most energy is spent in working against gravity. This prompted Van Ninhuijs to design a magnetic combination for the interior of the joint: a magnetic 'ball' that fits in a magnetic ‘socket’. By choosing the direction of these permanent magnetic fields wisely, he was able to have the joint move freely in the horizontal plane, whereas in the vertical plane the magnetic forces compensate for gravity. The PhD candidate says the design is unique and has been patented.

Surrounding the magnetic core, Van Ninhuijs made a second ball-and-socket joint, again with a permanent magnetic ball and this time a socket with coils - electromagnets capable of supporting active movements in a particular direction. “This requires relatively little power. If we had also compensated for gravity with electromagnets, the joint would need ten times as much energy.”

The PhD candidate has not yet got as far as actively controlling the joint. So he hopes his work will be continued. “My research is part of a larger project with various partners, so I'm hopeful this will happen.” In the unlikely event that his invention does not reach muscle patients, he foresees another future for his magnetic gravity compensation. “The principle is much more broadly applicable. Certainly in industry; for example in robot welding.”

Discussion