Home Stretch | Curved solar roofs

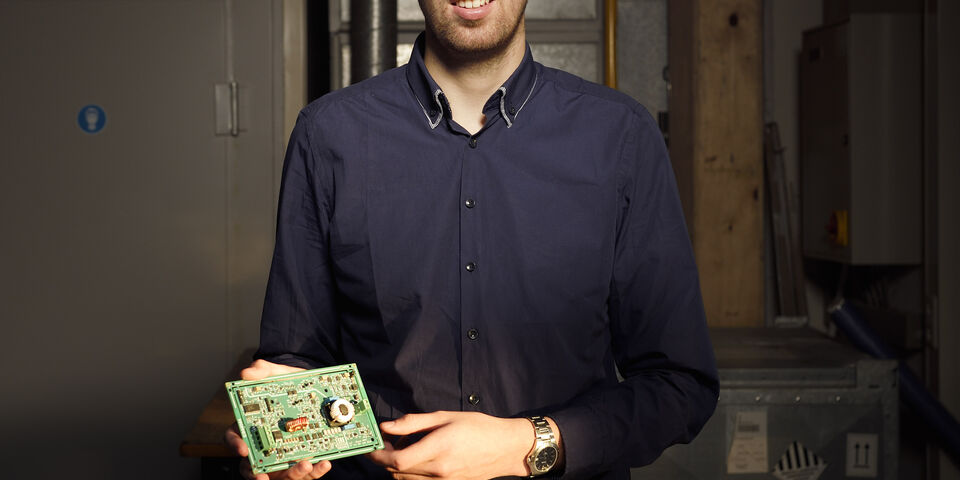

After his successes as ‘Chief Power Train’ in the first Solar Team Eindhoven, Arjo van der Ham returned to the student team for the subject of his final project. He devised a way to fit the solar-powered care with a ‘normal’ curved solar roof, without this reducing the output in solar energy.

The roofs of solar-powered car Stella and its successor Stella Lux are remarkably flat. For good reason, as alumnus of Electrical Engineering Arjo van der Ham explains: “The solar cells are switched in series; this means that the current running through every cell is identical. As a result, the cell that catches the least incident light actually determines the yield of the entire panel.”

It also means that a curved solar roof, with the contours of an ‘ordinary’ car, would be considerably less efficient than a much flatter roof: for then there are always cells that do not get the direct sunlight, which therefore limit the amount of power generated. “I have calculated that the efficiency of a solar car in the shape of a Volkswagen Beetle would be 74 percent, as against 97 percent for Stella.”

This is why the 381 solar cells of Stella are divided into three groups, with the cells within each of those groups lying in a virtually flat plane. This comes with two drawbacks, however, says Van der Ham. “Firstly, it does not look neat: it is not entirely in keeping with what people think a car should look like. Also, it is not necessarily good for the aerodynamics of the car.” In short, for the shape of the roof you would really like to have more freedom in the design of a next generation of solar-powered vehicles.

Tricks for cells covered with bird droppings

Now there are tricks already available to restrict the harmful effects of shaded cells or cells covered with bird droppings. “The cells performing worse can simply be automatically removed from the circuit, and you can then divert the current via a bypass. This is being applied widely even now for solar panels on buildings.” Whilst that solution is cheap, it does mean that you have no yield at all anymore from the cell switched off. For a high-tech system like the one used in a solar-powered car –certainly one that you wish to win contests with – that is not a satisfactory solution, Van der Ham thought.

Therefore he divided the solar cells into a large number of groups, and subsequently used smart converters to guide the electric power from the best-performing groups to the weakest cells. “In principle, in net terms you then attain the full yield, the only losses being suffered in the converters.” Depending on the exact degree of efficiency of those converters, the exact shape of the roof, and the properties of the incident sunlight, Van der Ham then determined the optimal number of solar cells per group. “For a solar-powered car in the shape of a Fiat Punto or Tesla Model S you can by means of this solution increase the yield of the panels from 79 to 94 percent.”

Van der Ham, whose final project was rewarded with a grade 9.5, is still meeting up every week with team members of the first hour. Although by his own account he never really had any special interest in cars or solar panels before his adventures with the Solar Team, he cannot let go of this subject anymore. Which is the reason why together with several former team members he is now beginning a commercial adventure in that direction, under the name of Atlas Technologies.

Discussion