Practical class Process Technology makes chemistry tangible

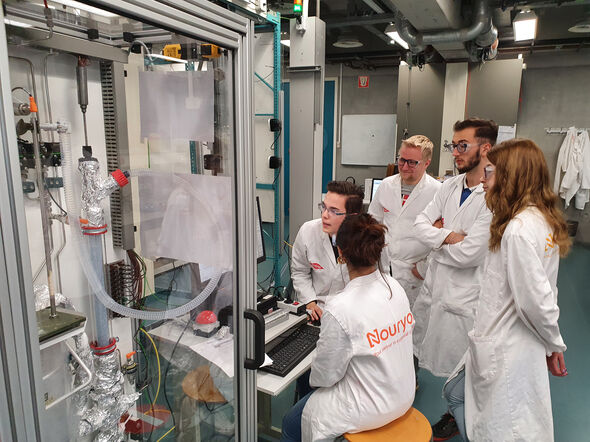

Wearing a lab coat and safety goggles, several third-year Chemical Engineering students are at work in Helix. Divided into several groups, they are working on thirteen different test setups. One stands out, assistant professor Ivo Roghair says: cryogenic CO2 capture. “It’s a wonderful device that deserves the attention of more people than just these eight students who get to work with it during this quartile.” Cursor took a look.

Third-year chemistry students have the opportunity this quartile to put the knowledge they acquired during their first years as students into practice. Courses such as Physical Transport Phenomena, Separation Technology and Reactor Engineering will truly come to life now. The lab in Helix has 13 test setups for a total of 72 students. They will work with two of these, one of their own choosing and one that was assigned to them. The end goal is that students learn to understand the process that occurs in these test setups. They design a measurement plan for their experiments and develop a computer model. The students will perform their measurements on a second test setup midway through the quartile, after which they need to present their measurement data to the group that follows them. Transferring acquired knowledge is another goal of this practical class.

Cryogenic CO2 capture

Mathy Kelleners is standing next to the cryogenic CO2 capture test setup. He is surrounded by a bubble column, a cooling tower and a test setup for membrane transport. He calmly explains to his fellow students how to fill the liquid nitrogen container for a cryogenic experiment. Fellow group member Robert Kwant explains that the temperature of nitrogen is -196 Celsius and that it is used to make a coil extremely cold. “When we conduct a mixture of nitrogen and CO2 on top of that column of glass particles, which has been cooled down to -150 degrees, the CO2 will frost up as dry ice as the nitrogen continues to stream as gas. This allows us to separate CO2 from nitrogen. We are writing a computer program that shows this process.”

Relevance

Assistant professor Ivo Roghair is particularly proud of this test setup. “The cryogenic CO2 capture test setup was made for our hands-on education. Apart from the current relevance of cryogenic CO2 capture, this setup is highly instructive for our practical classes. In addition, seeing it in action is a spectacular sight.” He says that his students are glad to return to in-person education.

There are other important aspects to this test setup. Roghair says that its construction was based on a thesis written by his best friend. Colleagues from TU Delft visited the TU/e lab because their students are competing in the Carbon removal category of the international XPRIZE contest. Roghair has joined the 4TU team CryoCOP as an academic advisor. If the students win, the Netherlands will receive a sum of 250,000 dollars as a first step to further develop this concept. In case the students reach the finish line, a sum of one million dollars will be made available to possibly apply cryogenic CO2 capture on an industrial scale.

Finally, this test setup was financed with the advanced study funds. Roghair: “I like to tell students that the money that wasn’t spent on the basic student grant, was eventually used to finance the actualization and modernization of their education.” He concludes by saying that the design of the test setup was an assignment of CE&C bachelor’s student Giel Bouwman. “It’s always nice when things cut both ways: you can offer someone a fun assignment and you get to use the result at the same time.”

Distillation

In the meantime, other students explain to each other how a process technologist should use a distillation column. Jurre van de Ven was just told that they need to separate a mixture of propane and methane and that they need to take a sample every ten minutes to measure the concentrations. “This can be done with light refraction, since the molecules have different shapes, and we use refraction numbers.”

Fellow group member Bas Oomen has just explained the bubble column to the others. “You blow air through it, and every ten seconds you have to measure how much oxygen the water absorbs and then write a computer model for that.” The students find the practical class useful but also feel that they have been thrown into the deep end somewhat. “You were only given a manual during the first round. Now we also need to use the data provided to us by the previous group.”

The fact that the students don’t make individual use of most of the test setups is not a problem. “During the final presentation they will realize that they’ve actually learned the same things,” Roghair says. “In the end, each assignment is about characterizing the flow, heat, substance transfer and chemical reactions, and to make the model more complete step by step. That seems like an unsurmountable challenge during the first week, but this practical class helps students realize that they can do much more than they imagined.”

![[Translate to English:]](/fileadmin/_processed_/a/a/csm_Procestechnologie_LV-hoofdfoto_5c6967e123.jpg)

Discussion