SOLID strikes the iron while it’s hot

After a five-year period during which TU/e student team SOLID focused primarily on iron powder as an energy source, the team now wants to broaden its horizon and become a leading team in the field of circular energy. A recent grant from City region Eindhoven will enable SOLID to use iron as an alternative method to store hydrogen. The first Iron-based Hydrogen Storage (IRHYS) reactor needs to be completed by the end of the year.

The fact that iron is a versatile substance is no secret to the members of TU/e student team SOLID. At the launch of the team over five years ago, the objective was to develop a new and clean energy carrier. The team took ‘metal fuels’ as the basis. These metal powders are relatively new and promising, because they are CO2-free, reusable, and have a high energy density. The idea: during the combustion of metal powders, energy is released, which produces metal oxide. This metal oxide can then be converted into combustible metal powder using clean energy sources, which makes for a sustainable medium for renewable energy storage.

SOLID spent the past few years working on this concept and successfully developed iron powder as an energy source, says Nick Hol. He works fulltime this year as head of project management at SOLID. “We also considered other metal powders, but since iron has a very high energy density and is compact, safe and widely available globally, it became apparent that we would focus on iron.” And it works. Previous editions of SOLID constructed a 20-kW installation that burns iron powder and releases heat, and went on to build the world’s first industrial installation at the Bavaria brewery of Swinkels Family Brewers.

New challenge

Now, SOLID is ready for a new challenge, Hol says. “We mostly concentrate on innovation and consider ourselves a bridge between the university and industry. And now that the metal powder technology has reached a point where it can be taken up by partners from industry to commercialize it and to complete the final steps of development, our most important work is done. We want to look beyond this point and not just focus on combustion, but grow into the leading student team for circular energy. Again, with iron in a leading role.”

Because you can’t just burn iron to produce oxidized powder, steam also does the trick, Hol explains enthusiastically. “If you put iron on a water kettle, you’ll notice that the steam forms rust. But apart from iron oxide, hydrogen is formed also. And that made us think, since hydrogen is a hot topic right now.”

Indirect ‘hydrogen storage’

That is why SOLID wants to use its new Steam Iron Project as an alternative hydrogen storage source. Because the current technologies for storing and transporting hydrogen come with a variety of problems. Since hydrogen has a low density at atmospheric conditions, it needs to be kept under high pressure to increase storage density. In addition, hydrogen gas is highly volatile and flammable, which creates a number of risks. In liquid form, it’s possible to store larger quantities per barrel, but converting hydrogen gas to liquid is a highly energy-intensive process.

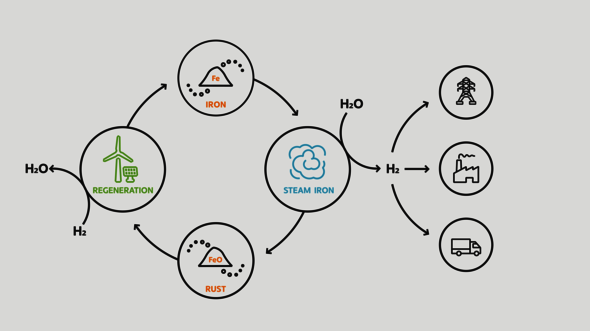

Iron-based Hydrogen Storage (IRHYS) might offer an efficient and safe alternative option to store hydrogen, Hol says. “We use steam to oxidize iron. In this process, hydrogen is produced, which we can subsequently filter from the rest products. The iron oxide can then be regenerated by adding hydrogen to the rust powder. This cycle is sustainable, and hydrogen can be stored and used when necessary.”

Hydrogen won’t actually be stored in the iron powder, incidentally: the hydrogen is in the water that produces steam. But the net effect of the IRHYS system is the same, Hol says. “In this system, iron functions as a catalyst to mine hydrogen from steam, the net result of which is hydrogen production. An indirect way to store hydrogen, so to speak. This method also makes it possible to store greater quantities of hydrogen per storage unit than you can with conventional methods. The biggest challenge is that there still is no clear, broadly supported shared vision for the future within the hydrogen community. That makes it difficult for us to introduce an entirely new concept. On the other hand, our expertise and innovation can also help determine the direction this technology will move into. A student team like ours can truly help move the energy transition forward, and that’s what makes this work so special.”

Bustling demo event

The team’s first step will be to build a reactor that needs to convert iron powder into iron oxide and hydrogen. This installation needs to be completed by the end of the year. The ambitious student team has already started several partnerships with, among others, DNV, Metalot, RIFT and TU/e. In addition, the team recently received a grant worth 50,000 euros from City region Eindhoven. “This grant will allow us to actually build the installation. And we will start on a large scale. Not another lab setup again, but a 1x1x2 meter installation that needs to produce 1 kilo of hydrogen per cycle. We are currently busy writing the software, making mechanical designs as well as schedules and safety studies. A large techno-economic feasibility study is also being carried out at the moment, and we’re working on a technology development roadmap to show that the concept also works from a business perspective. Everything needs to be worked out so that the new team can start of with the practical side next academic year. And that will no doubt be a great year. We’ve set a course towards a bustling demo event.”

SOLID is still looking for students. Are you interested? Contact the team at info@teamsolid.org for more information.

Discussion