3D-printed cookies crispy at odd places

Printing cookies with a laser is a bit more complicated than baking them in the oven, but you get a range of new possibilities in return. It allows you, for example, to determine with millimeter-precision the exact spot where your baked good needs to be crispy. Mechanical engineer Nicky Jonkers partnered up with TNO and Wageningen University & Research to investigate how you can use a 3D printer to add certain structures to food products. He will defend his doctoral research at the department of Mechanical Engineering today.

Will there be any 3D-printed bitterballen afterwards? It’s a question Jonkers has had to answer frequently during the run-up to his PhD ceremony. The idea of printed food seems to speak to people’s imagination. Especially at Mechanical Engineering, where most people primarily tend to focus on plastics and metals. There won’t be any printed bitterballen, by the way. In fact, Jonkers couldn’t even eat the cookies he printed for his research, because they were created by laser with a printer that’s also used for pharmaceutical applications. “That printer contains substance leftovers that a healthy person shouldn’t want to digest.”

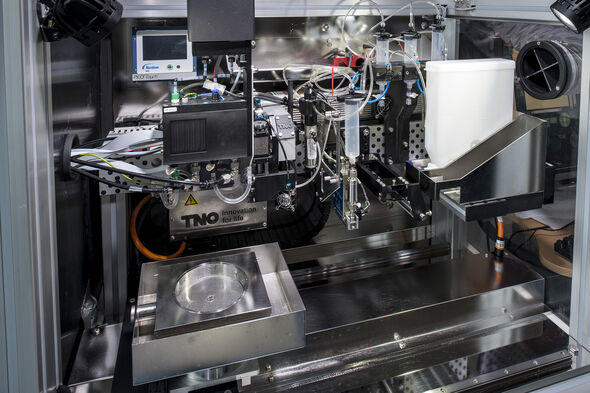

Still, printing food stopped being a futuristic sounding concept some time ago. There’s even a pop-up restaurant that serves 3D-printed meals. The most commonly used method for creating these meals is known as Fused Deposition Modeling, in which a printer fuses together different layers of food. The machine with which Jonkers created his cookies works in a slightly different way: it melts powder particles with a laser. “You add small layers of powder and then use a laser to bind that powder together at a location of your choosing,” Jonkers explains. When you brush away the excess powder afterwards, the printed object will appear.

Density

A powder-based printer allows you to locally determine the desired object’s properties. You can set the laser’s level high or low, make it move fast or slow, or let it follow different routes. Each of these variables influence the printed object’s density. And that density influences the structure and texture of food. In the case of Jonker’s cookies, which are made of starch, maltodextrin and palm oil, a higher temperature leads to a higher density. “The powder binds better because of this, resulting in an increased stiffness, as a result of which the cookie won’t break that easily.”

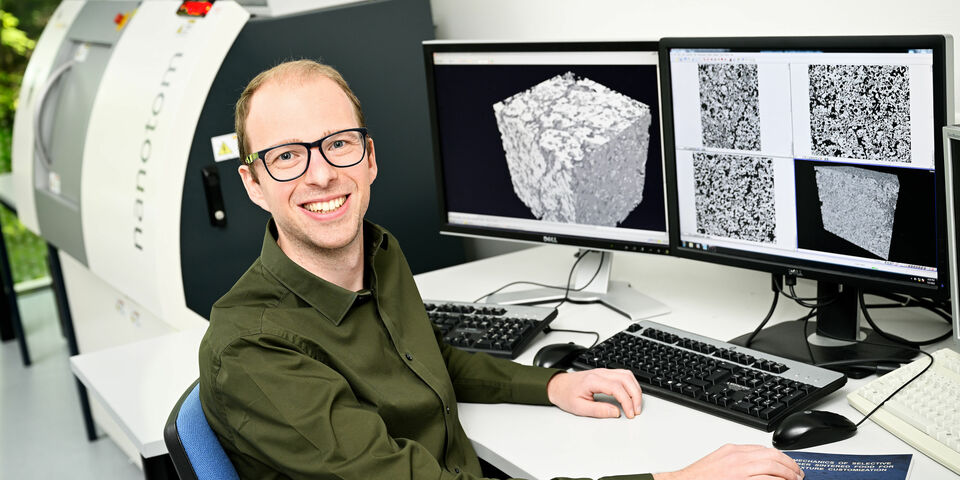

The amount of air in a printed food product, how successfully it was melted together and the level of porosity all influence the mechanical properties, Jonkers explains. “When you’re chewing a cookie, you’re basically testing those properties. But I studied them in the lab by making X-rays and by simulating chewing movements with a machine that has two plates.” This also allowed him to study the breaking behavior of his cookies, for example, and to find out whether they break apart into two halves or into multiple smaller pieces. Nevertheless, none of these methods provide a definitive answer to the question of what happens to a cookie in a person’s mouth, the PhD student says, since saliva, for example, wasn’t included in the test.

In order to predict the mechanical behavior as a result of the printing process, Jonkers developed a model with which he can create ‘digital cookies.’ The model also saves him a lot of time and money. “Printing a cookie of 1,5 centimeters takes two hours, which is why these cookies are still extremely expensive right now. Digitally however, you can ‘print’ as many designs as you like. This testing method is much faster.”

Experience

But it takes an actual human mouth to determine how the eating experience will be affected by the new structures, the PhD students acknowledges. Ultimately, that experience is what Jonkers’ research is all about. New structures in food can add new dimensions to that experience. “Each bite can feel slightly different, for example, or you can taste something inside that you didn’t expect simply from looking at the food product.” This is potentially of interest to restaurants. But laser printing can also be beneficial to the medial world. “Some people can only digest a minced diet because they have trouble chewing. Take a hard food product like carrots for example. If you can print that but with a softer structure, people will feel as if they’re having an actual meal. Otherwise, they’ll only be able to eat mashed food.”

But we haven’t reached that point yet, Jonkers says. “I’ve looked at the possibilities that a 3D printer offers in a general sense. But in the future, you want to be able to say: I want a cookie that’s crispy in one place and airy in another. That isn’t possible yet. It will take more research. But we’ve laid the foundation.”

Discussion