- Research , Home Stretch

- 12/09/2023

Home Stretch | Reshaping ship locks

Many ship locks in the Netherlands, which were built in the previous century, are nearing the end of their lifespans and will need to be renovated over the next few decades. This poses a major challenge to the Ministry of Infrastructure and Water Management’s executive agency Rijkswaterstaat, which is responsible for this task. PhD candidate Sjoerd Knippenberg developed a product platform to standardize the design (and redesign) of ship locks, supporting Rijkswaterstaat in the renovations. He will be defending his dissertation at the Department of Mechanical Engineering today.

In the Netherlands, ship locks are an important element in the waterway network, as they regulate water level differences between waterways, thus making them suitable for navigation. Rijkswaterstaat (RWS), which – among other things – is responsible for the construction, management and maintenance of ship locks in the Netherlands, built many of these locks in the first half of the twentieth century.

“As ship locks have a lifespan of about a hundred years, many of them will have to be renovated in the coming decades,” says Knippenberg, whose PhD research was carried out in collaboration with RWS. “In addition, many ship locks don’t have sufficient capacity to meet modern-day needs when it comes to maritime transport, so the planned renovation also presents an opportunity to make sure they are brought up to current standards and requirements,” he continues.

Tailored versus off the rack

Most of the current ship locks have been designed to meet location-specific demands, which led to a wide range of different, unique designs. Now that they all have to be renovated, why not take the opportunity to standardize these designs where possible? “You might compare it to a tailored suit versus an off-the-rack one,” the PhD candidate explains. “A tailored suit fits perfectly, but it’s labor-intensive and expensive to produce. Off the rack clothing isn’t tailor-made and might not be a perfect fit, but is good enough to cater to a large group of users.”

The same efficiency is needed for the renovation of the ship locks. You don’t want to look for the perfect solution for every lock, but find one that can be generally applied to multiple ones. “By devising more standardized solutions, the renovation does not only become more efficient, but also quicker, cheaper and even more sustainable, as it’s easier to reuse the standardized lock elements,” Knippenberg argues.

Product platform

Rather than being standalone, his work builds upon PhD research by TU/e alumnus Tim Wilschut, who studied the similarities between ship locks and, based on this, identified ‘lock families’. These are groups of locks that are similar to a certain extent. As a next step, Knippenberg developed a product platform that can help find the best design choices for a lock family. “The goal was to provide Rijkswaterstaat with a practically applicable tool that would help them renovate the locks.”

The product platform is made up of such things as the standardized ship lock elements and their specifications. “A ship lock consists of a number of basic functional elements, including gates, actuators and chambers. These come in different types, such as miter gates and lift gates, as well as different materials, such as wood and steel,” Knippenberg explains. This means there are a lot of choices to be made. “The question is: what’s the ideal solution for a group of ship locks?” For one lock family this may be wooden miter gates, whereas for another group steel lift gates work best.

A practical guideline

The ideal choice depends on many factors. “For instance, quite often it concerns a partial renovation, where only certain parts need replacing. This means you’ll have to take the existing elements into account,” Knippenberg says. “You can’t just replace a lift gate with a miter gate, otherwise you’d have to replace the entire lock.” He adds that while on the one hand this poses certain limitations, those limitations also make things easier because in the end one is generally left with only a few options.

The product platform he developed takes account of different factors that are important for the choice of design and also the compatibility with existing structures. As such, it makes for a practical guideline that can help RWS make the right design choices. “You can’t apply it anytime, anywhere, for example because there are monuments whose existing constructions may not be altered. Or sea locks, like the ones in Terneuzen and IJmuiden, which are so big and unique that they’ll always require custom solution,” he points out. “But for renovating the majority of locks it’s a highly applicable method that at the very least makes for a solid point of departure.”

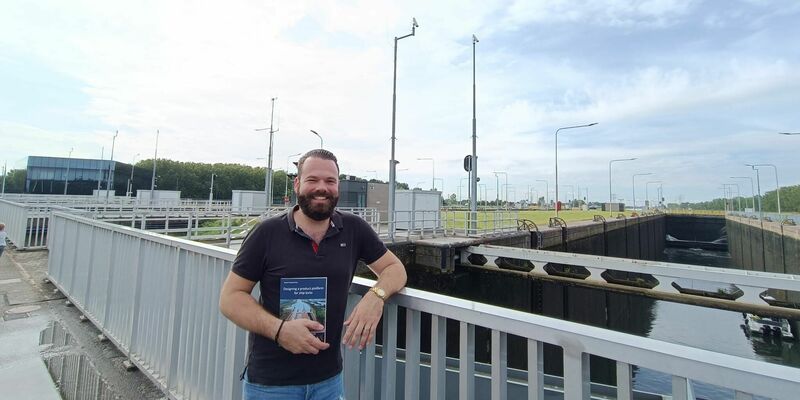

Spooldersluis

The product platform was tested in practice in the renovation of the Spooldersluis ship lock in the municipality of Zwolle. “The cool thing is that this method yielded solutions that are in keeping with the design choices made by Rijkswaterstaat experts earlier. This shows that the method works well,” the PhD candidate says.

Furthermore, the product platform’s scope of application goes beyond supporting the renovation of ship locks. “I think you could quite easily apply the same methodology to other large projects, such as the renovation of bridges, tunnels and viaducts,” he asserts.

For now, however, Knippenberg is especially curious as to how the renovation of ship locks will go in the coming decades, and hopeful that his method will make a positive contribution in this respect. He believes it’s important RWS continues to develop the platform. “Essentially, the platform is a collection of all knowledge you need to make the right design choices. So if somewhere down the line it turns out that a certain solution isn’t ideal after all, or if new technological innovations pop up, you need to incorporate this information into the platform and perhaps throw something else out. The platform is never entirely finished, it must always keep developing.”

Discussion