How non-disclosure agreements hinder chip research

Open-source foundries could pave the way for reproducible chip research

Commercial chip foundries operate under strict confidentiality. Because of that, scientists are often unable to disclose how their chips are made. This lack of transparency means that others cannot validate their findings. New open-source chip foundries may change that, argue Professor Peter Baltus and postdoctoral researcher Elles Raaijmakers from the Integrated Circuits group.

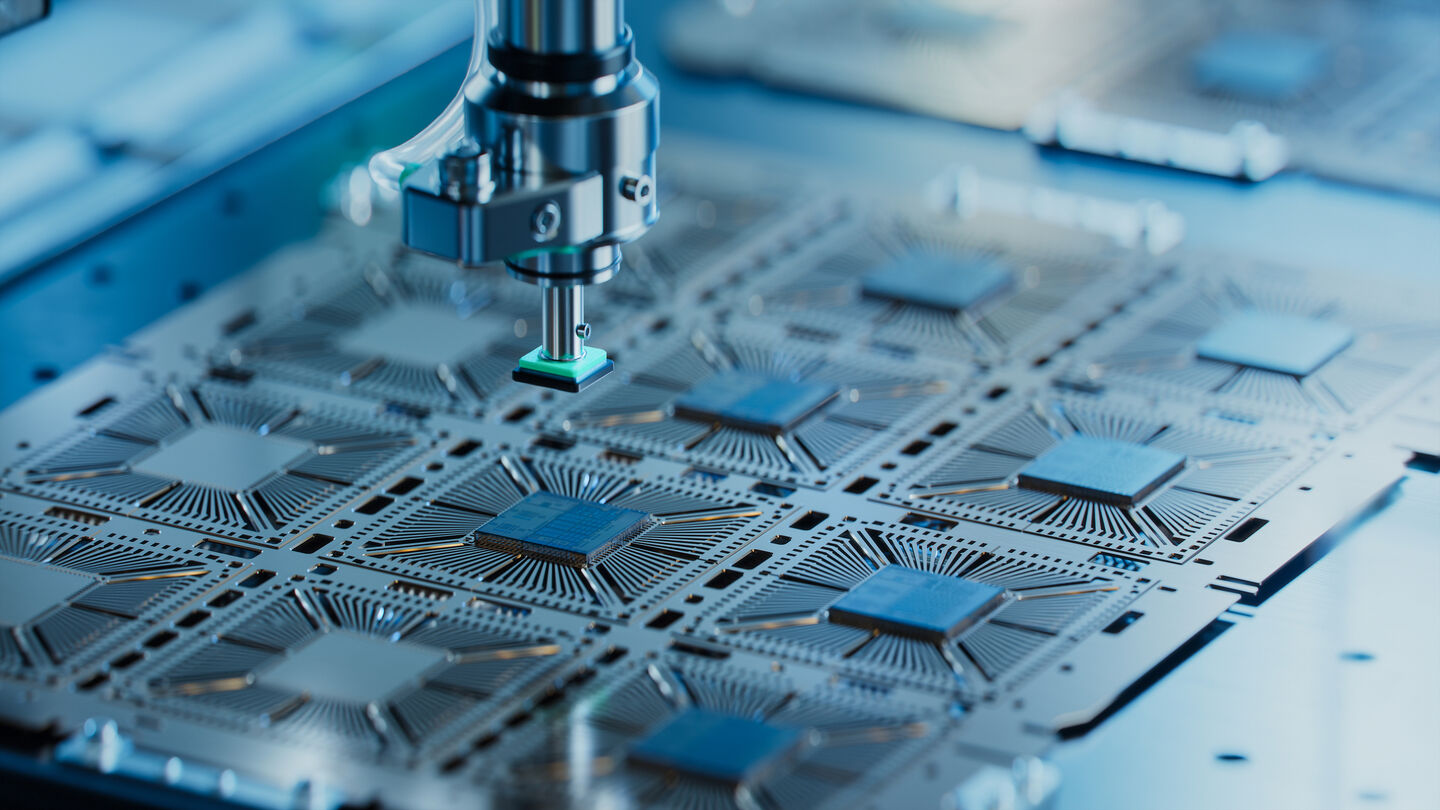

Anyone designing a chip for scientific research who wishes to publish their results must provide physical proof of their design: a manufactured chip and a photo of it in the publication. Chips can only be manufactured at foundries such as TSMC in Taiwan, which produces millions of chips each day. The Integrated Circuits group in the Department of Electrical Engineering, headed by Baltus until recently, also uses such foundries for research. “We have chips made about five times a year,” Baltus explains. “For each design, we receive 25 to 50 chips. Even with a significant discount, each design still costs around 25,000 euros.”

However, cost is not the biggest issue for scientific research. The greater obstacle lies in the fact that large commercial companies insist on keeping the technical details of chip development confidential. Researchers working with such foundries must sign a non-disclosure agreement (NDA), making it impossible for others to reproduce their research, which is a fundamental principle of science.

Blurred images

Because so much information is withheld, peer reviewers at scientific journals have no way of verifying whether everything in a paper is accurate. Baltus explains: “Reviewers read the article and think: the story seems plausible, it’s a step forward compared to existing work, it might be correct. But they can’t be sure, because essential information can’t be shared due to the NDA. We assume most publications are accurate, but that’s really just a feeling.”

To illustrate this, postdoc Elles Raaijmakers shows an article published in the prestigious journal Nature. The supplementary materials contain blurred images, hidden because of an NDA. “That doesn't show you anything useful,” she says.

One advantage of chip research is that you can test a chip to see if it works. Yet, cases of scientific fraud have still occurred. Baltus mentions the example of Adrian Maxim, a U.S. researcher who had at least 48 papers retracted. “He was well-known, a keynote speaker at many conferences, with impressive results. But it turned out he’d never had any chips made, fabricated the measurements, and even Photoshopped the chip photos. Even his co-authors didn’t exist.”

It took years before Maxim’s fraud was uncovered. Mainly because no one could verify his results due to the NDAs, Baltus says. “If others had tried to reproduce his chips, he could simply say: ‘Your chip is different, but I can’t tell you how.’”

Major interests at stake

Large foundries that use cutting-edge technologies have good reasons to keep their production processes secret. “They’ve made massive investments,” says Baltus. “If a foundry were to lose even ten percent of its sales because a competitor copied its production ‘recipe,’ that could mean millions of euros lost per day.” Commercial companies therefore have no incentive to make their manufacturing specifications public.

But older chip factories do. As customers move to more modern foundries, older facilities struggle to maintain production volumes. This, Baltus explains, led about five years ago to the emergence of the first open-source foundry, in which Google played a major role. There are now two open-source foundries, with a third preparing to restart operations.

When the technical details of a production process are no longer largely confidential, the transparency needed for science becomes possible, Baltus argues. Not all research chips can yet be manufactured in these open-source facilities, but Raaijmakers and PhD candidate Jelle Verest have already taken the first step by having chips produced at one. It took a year, but they’ve just arrived.

Validating chips

The researchers now plan to do something that was previously impossible: validate chip models. “Jelle calculated the expected processing speed of several existing models,” Raaijmakers says. “He came out at 125 gigahertz (GHz), but that can’t be right—that’s about a factor of four too high, we think.” Verest recreated the chip design and can now measure the actual performance.

If it turns out that the chips’ maximum operating frequency is closer to 35 GHz, as Raaijmakers expects, the researchers can share that data with the model’s developer, who can then improve it. “That’s how chip research should work,” says Baltus. “This way, we can build on each other’s work much faster and more efficiently.”

Isn’t this open-source approach already obsolete, since major foundries are so far ahead technologically? Baltus doesn’t think so, because in chip design, companies may do a lot of internal research using the latest technology, but their capacity is limited. And they can only share knowledge with other parties to a limited extent. In the open-source community, you have more people collaborating, and that can take you a long way, he argues.

Raaijmakers agrees: “I often mention a game where players learn to fold proteins. It is like an enormous 3D puzzle. It has tens of thousands of users, many with no background in biochemistry, yet they came up with new ideas. Players even discovered a protein structure faster than a supercomputer.”

Designing chips

That concept inspired her to create a similar game for chip design, to help build the critical mass needed to make open-source chip development take off. In the game, currently under development, players gradually learn how to design a chip. It’s aimed at students initially, but the goal is to make it available to anyone interested. “We hope people will start designing chips that can actually be manufactured,” Raaijmakers says. Other projects are also underway to get more people involved in chip design, starting with existing educational kits for children aged eight and older, which Raaijmakers distributes through local libraries.

There are countless potential applications for new chip designs that currently remain unexplored simply because of the high cost, Baltus adds. “One of our projects focuses on inspecting the drinking water network. Water leaks are extremely costly to locate. But if you could continuously monitor the system by placing a chip every few meters, that problem would disappear.”

Open-source foundries could make this feasible by allowing small-scale, low-cost production runs. “That could open doors for all kinds of applications,” Baltus says.

A bargain

These small production runs are affordable because foundries can place multiple projects on a single wafer—the silicon base plate used in chip manufacturing. This lets multiple users share the production costs. That’s how Raaijmakers received 100 chips from an open-source foundry for ‘only’ 10,000 euros. “A real bargain,” she says.

Could this development truly transform chip research and production? Both Baltus and Raaijmakers cautiously say yes. But Baltus stresses that it depends on building a large enough community interested in chip design. If open-source foundries continue to grow, it would certainly be a positive development for science, he believes. “If nothing else, it would mean commercial companies could no longer ‘hold our results hostage.’ More openness would definitely reassure me.”

This article was translated using AI-assisted tools and reviewed by an editor.

Discussion