Wageningen yearns for the knowledge from Eindhoven

Read more- Research

- 26/04/2018

Wageningen yearns for the knowledge from Eindhoven

Scientists from the university of Wageningen (WUR) and from TU/e are already finding each other on several fields of research, but the members of the Executive Boards of both institutions believe that there is more to be gained. The coming years they want to strenghten their collaboration and they hope that their scientists will be even better in finding each other. "Because we speak the same language."

Professor Jakob de Vlieg, professor of Mathematics and Computer Science and since early 2017 the Eindhoven coordinator for the WUR-TU/e cooperation, has for more than a year been hammering on the opportunities that such cooperation holds. During the two meetings which he organized at TU/e at the end of January and the end of March for researchers and staff members, both of which were attended by some thirty people from nearly all departments, reactions were very positive.

On the Eindhoven shop floor people also realize the potential, although there are some questions as well about which Wageningen group or partner researcher may be eligible. According to De Vlieg that must be charted properly, among other things on the basis of meetings of this kind.

At this moment in various areas researchers from both institutions have already found each other in recent years.

Plasmatechnology

So is TU/e professor Guus Pemen working together for some time with WUR researcher Masja Nierop Groot on a method by which plasma, or water treated with plasma, used to decontaminate crops and packaging materialsare. According to Nierop Groot this technology is not entiely new. “Our group has worked for many years on this, but it is still taking us too much time. A PET bottle, for instance, takes us minutes, and that needs to be reduced to seconds. Since we possess a lot of knowledge about applications, whereas TU/e has a great deal of technical plasma knowledge, I think that our cooperation can be very fertile.”

Pemen explains that plasma can be used for decontamination in three ways. “You can expose the product directly to a plasma, or in such a way that there is contact only with the reactive molecules produced in the plasma. The mildest variant is exposure to plasma-activated water.” Which method works best, depends on the specific situation, he says.

Plasma-activated water can be made by generating a plasma near the surface of (running) water. The plasma then makes the nitrogen and oxygen in the air so reactive that substances including hydrogen peroxide and peroxinitrite arise in contact with water. Dissolved in water both substances are then active as disinfectants.

More environmentally friendly

Pemen: “This plasma-activated water can be nebulized, for example. Tests we have conducted jointly with Wageningen have shown an effect on bacteria and fungi similar to that of pesticides.” A great advantage, though, is that plasma-activated water is much more environmentally friendly. “The disinfectants are short-lived: within a day they have been converted into innocent compounds again”, says Pemen.

His Wageningen colleague Nierop Groot sees plasma as an addition to existing decontamination techniques, such as heating, exposure to UV radiation, and ‘wet’ methods like washing with chemicals. “In comparison, plasma is a relatively mild method, suited for use with dried herbs for instance, which you don’t want to moisten and cannot heat too much either. Besides, decontamination with plasma is possible even at a temperature of around seventy degrees.” Besides this it also offers the possibility to tackle bacteria that can survive very high temperatures, she says. And it may be very interesting for the decontamination of the latest generation of PET bottles. "These tend to be made thinner all the time, which makes them less resistant to heat.”

Fertilizer

Accelerating the growth of plants with plasma-activated water is also possible, through the nitrogen compounds it generates in that water. Polo van Ooij, Chief Technology Officer of VitalFluid, a spin-off of TU/e, discovered the fertilizer-like properties when he tried out the plasma-water on the miniature vegetable gardens that supermarket Albert Heijn hands out sometimes. “The yield was five times as high”, he says. “It appeared that after about fifteen minutes the decontaminants are converted into mostly nitrite and nitrate.” Which are precisely the two main components of fertilizer.

This discovery provided an entirely new perspective on the sustainable production of fertilizer. “You should see the process like lightning above water”, says Pemen. “That lightning can be generated by means of electricity from solar panels or windmills and the only thing you need in addition is air and water and some minerals.” In contrast to the current production methods for fertilizer, no CO₂ is released in this process, and you can apply it on a small scale and locally, so also in developing countries.

According to Pemen one thousand liters of liquid fertilizer can be made with plasma with one kilowatt hour, which corresponds to the traditional production method of fertilizer. “With our first pilot reactor [see the film above] we make one hundred liters per hour. That may be small fry, but meanwhile we are moving towards one thousand liters per hour. A couple of such reactors would be enough for a horticultural farm.”

One of the remaining challenges is to make plasma-activated water with precisely the right mixture of disinfectant and growth-enhancing compounds. “That balance depends on the exact properties of the plasma which we use”, says Pemen, “and that is one of the very things we would like to test along with our colleagues from Wageningen.”

Funding

It is by these examples of collobarations that already exist, that coordinator De Vlieg is convinced that the two knowledge institutions need to join forces to develop sustainable and coherent lines of research. This should be done in cooperation with the business community. Apart from this, they need to think of a structured way to look for fundingfor their research. It can be found at NWO, but often also at specific European funds which at this moment have hardly been identified for TU/e.

Research from all TU/e departments qualifies for cooperation with WUR, is the firm conviction of De Vlieg. “Our Strategic Areas dovetail perfectly with it as well and I also see a great many opportunities in the reuse of technologies that have already been developed in Eindhoven , though in an entirely different domain; agrifood.”

Likewise, the Wageningen Rector Arthur Mol sees the huge added value which intensification of the cooperation will bring. In this view he has the Eindhoven Executive Board on his side. President Jan Mengelers and Rector Frank Baaijens speak of good chemistry between the two boards – which may not be a decisive factor straight away, but they think that this click is definitely there on the shop floor too. “Our researchers speak the same language”, says Mengelers. “Of course, Wageningen also has contacts with Delft and Twente, but the fact that our institutions are relatively near each other is an advantage already.”

Mol, who took office in 2015, is clear about the Wageningen preference for Eindhoven. “Within the 4TU context, of which Wageningen became a part in 2016, Eindhoven is the most complementary partner for us. There is lots of common ground between the two universities and in fact there is hardly any duplication of research at all. Moreover, our universities are organized in a practically identical manner: many things are left to the shop floor, there is little hierarchical direction, we have no employees who make a great fuss, but indeed, they are people showing a hands-on mentality, who want to tackle and solve problems. The result is that people can switch quickly at the level of the shop floor as well.”

‘Switchable’ glass

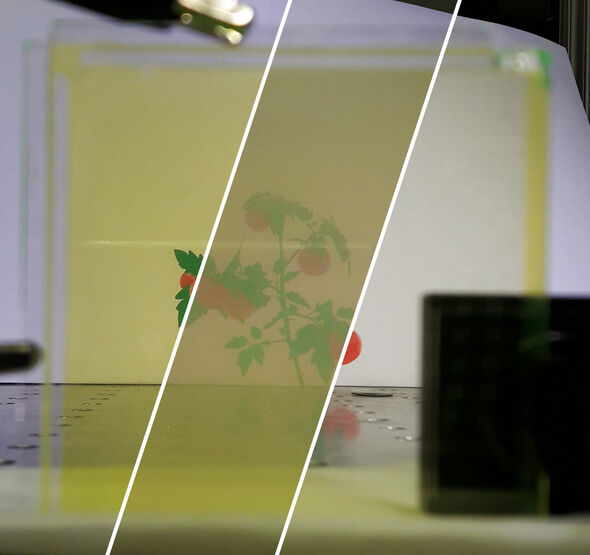

A nice example of that fast switching can be found in a project where researchers from Eindhoven and Wageningen have found each other in one of the most conspicuous components of the Dutch glasshouse cultivation: the roofs. Together they are working on a method to make optimum use of sunlight with ‘smart glass’.

In winter the tomatoes and peppers in our greenhouses long for every little ray of sunlight, whereas the full sunlight in the middle of summer is too bright, so that then the greenhouses are opened up so as to prevent overheating. Which is awkward, for as a result the added CO₂ escapes from the greenhouse and voracious insects get the chance to sneak inside.

The regulation of sunlight in greenhouses is now done by means of curtains or the application of a special coating. That is not optimal, Silke Hemming concurs, head of the Greenhouse Technology group in Wageningen. “On a dark, rainy summer day you would rather get rid of that coating. You can also use a curtain, but on a hot, sunny day that impedes the exchange of air. A system that allows you to respond directly and flexibly to the weather conditions would be far more practical.”

Peer+

In Eindhoven work has been done for years now on so-called ‘switchable’ panes, which can by means of electric tension be made darker or indeed more transparent. The Smart Energy Glass of TU/e-spin-off Peer+, which was acquired in 2014 by chemistry giant Merck, even converts the absorbed light into electricity. The technology is based on a thin layer of liquid crystals, of which the orientation, and thereby the effect on light, is manipulated with an electric tension.

With liquid crystals you have many different options, says TU/e researcher Michael Debije from the Stimuli-Responsive Functional Materials and Devices group. “You can choose whether you want to block ultraviolet light, or infrared or green light. You can also make diffuse light from direct sunlight.” And this can be done depending on the time of day or the sunlight conditions. While the options seem infinite, it is very expensive indeed to test all the options on real crops, which could easily require switchable panels measuring several square meters.

For this reason WUR researcher Hemming is overjoyed with the small test panels that have been made by students of Debije. “Moreover, Michael has charted for us in a magnificent way what technology there is already in this area.” Now the search is for a manufacturer who can produce somewhat affordable bigger panels, with which the effect of the smart glass on horticultural crops like tomatoes, peppers and cucumbers can actually be researched.

Hemming already has a material in mind for small-scale practical tests. “It is a switchable system with which you can vary both the permeability and the extent to which the light is made diffuse; it turns out that diffuse light is favorable for virtually all crops.”

In the area of data sciences in particular Rector Mol sees great opportunities in the relevant knowledge that is present at a fundamental level at TU/e. “In Wageningen we also engage in data sciences, but that is mostly application-oriented. We are assiduously looking for knowledge at a fundamental level, what is exactely that Eindhoven has in store.” Mol thinks this especially concerns the application of sophisticated analytical techniques on the large datasets that WUR disposes of.

“Think of Dutch agricultural data in the area of crops, production, entrepreneurial data and climatological data. Far more can be retrieved from them, but we often come up against the boundaries of our capacities", he says. "But you may also think of our datasets in the area of genomics, whereby we can gain more insight into the structure and the functioning of the genetic material of plants, animals and micro-organisms, and our worldwide databank on soil samples."

Mol tells that all kinds of companies are obviously keenly interested in these data and approach WUR for cooperation, "but at present we are very cautious about teaming up with external parties. Such cooperation might result in us giving away more than we would actually want. In this respect we regard Eindhoven as the ideal friendly partner, who knows exactly what can be gleaned from our datasets.”

Brabant

For Mol and WUR it is also of great importance that Brabant is an essential area for agrifood in the Netherlands. “We specifically had to point that out to the Eindhoven Executive Board, for they had not really assessed it in that way”, says Mol with a smile. “Although the Brabant agrifood sector is vast, it also has to contend with plenty of environmental issues, for which a technical component may provide solutions. This is something that the provincial authorities also find important and encourage and which we as WUR can go on with partly, but of course TU/e is a very interesting partner for us in this respect.”

All of this are great opportunities and chances but what is to be the biggest gain by TU/e in this cooperation? For Mol that is evident: “TU/e can hereby gather insight into and contacts in a sector and with companies which it has no access to at this moment, because agrifood for Eindhoven is an uncharted area. What elements are at play there, what issues present themselves there, how exactly do things work in the chain, how is the sector organized? All these are matters with which we are quite familiar, of course.”

Decorative plant cultivation logistics

TU/e professor Tom Van Woensel greatly benefited from that Wageningen knowhow when in 2015 he was working together with researchers and students from WUR in DaVincᵌi, a research project in the area of decorative plant cultivation logistics. He regards the logistics chain in decorative cultivation as a complex chain that is undergoing significant change. FloraHolland, the cooperation in which the sector has united itself, wanted to get a better view of future developments, so it tried to find a good strategy.

It is definitely worthwhile looking at further cooperation in this area with WUR at some point in the future

For a logistics researcher this is a very fascinating set of questions, although it comes with the additional snag that the goods that are transported have a limited shelf life. Van Woensel: “Plants and flowers are supplied from all over the world, in many different ways, they are stored somewhere and traded and eventually bought by consumers who expect to enjoy their freshness at home for a week more.”

Van Woensel and his PhD candidates and students investigated the possibilities of more strongly demand-driven, more efficient decorative plant cultivation logistics. “In order to be able to do so properly, though, as a logistics researcher you suddenly also need to possess knowledge about the shelf life of all kinds of flowers and plants. In addition, you need to know what the effects are of different forms of transport and storage. In this project we could benefit significantly from the knowhow that is available about this at WUR, whereby we could enter their data into our logistics models.”

The conclusion we arrived at was that good cooperation between all the partners in the chain is the only way to keep costs under control. Van Woensel: “The question then is how you ensure that each partner sees an advantage in it and actually gets that advantage. Tough subject matter, really different for us due to the perishable goods, but very fascinating at the same time. It is definitely worthwhile looking at possibilities for further cooperation in this area with WUR at some point in the future. If there are funds available to do so, of course, for finding those is certainly not a piece of cake in this sector.”

Acceleration

Rector Mol wants the WUR-TU/e cooperation to accelerate in the next three to four years and wants to see a strong increase in the number of projects. Whether this will lead to joint master’s programs is something he cannot say for now,, although he is certainly open to this. “We are also definitely interested in the system of the PDEng programs of the universities of technology, which we don’t have yet, but we would certainly want to start a number of them.”

Within the themes in which WUR and TU/e will find common ground before long, Mol expects that his institution will invest extra funds. “That is largely self-interest, as cooperation with other institutes is really vital for Wageningen.” Will there be extra funds coming from Eindhoven too? Mengelers mentions the possibility of setting up an alliance fund for this cooperation in due course, with resources that researchers can tap into. About the size of that fund he cannot say anything at this moment, though.

Sustainable Food Initiative

An initiative in which both universities already participate, and which is supported by the Ministry of Economic Affairs, is the Sustainable Food Initiative (SFI). A year ago the first signatures for this initiative were placed. It really needs to get started before the summer holiday. In addition to WUR and TU/e, many big companies from the food sector participate in it, including Unilever, Cargill, KraftHeinz and Heineken.

This initiative must develop into an active hub to which researchers, innovators and companies from all over the globe can make a contribution. At the end of March the Wageningen researcher Remko Boom made a presentation about it at TU/e. What is special about the SFI, in his view, is that it involves parties from the whole food chain.

“SFI must develop into a community, within which research results are shared actively. The industry needs to tell us what we can help it with, and it’s no problem if that should be a moonshot. Some goal of which we are not certain whether we are going to attain it, but for which it makes sense to share such a progressive ambition. Also, it is not enough just to conceive of things and develop them, they must also be actually implemented. That is another essential pursuit of the SFI.”

Main illustration | Pascal Tieman

Discussion