At the cradle of fruitful collaboration with ASML

For years Gerrit Kroesen has been maintaining a close connection to the chip machine manufacturer

By agreeing to jointly develop a 10-year strategic research roadmap and making plans for a new cleanroom, ASML and TU/e recently strengthened the close relationship that had already been established between the chip machine manufacturer and the university. It is the fruit of a long and intensive collaboration that goes back some twenty-five years. Former Dean of the Department of Applied Physics Gerrit Kroesen stood at the cradle of the fruitful friendship and still helps to “grease the wheels.” He is what he calls: “an oil man”.

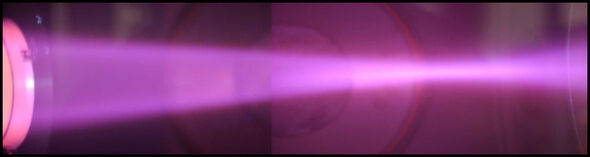

It was around the year 2000 that the first PhD candidate from Applied Physics (and TU/e) started his doctoral research in collaboration with ASML. Erik Kieft explored different sources to generate Extreme UV light (EUV), (with Joost van der Mulen as supervisor and Gerrit Kroesen as PhD supervisor) - which turned out to be tin - and obtained his doctorate with honors. In return, ASML gained knowledge that the company still applies to this day in the development of the latest EUV machines. Without realizing it, Kieft opened the door for many future TU/e PhD candidates, and a structural collaboration was born.

According to Gerrit Kroesen, it is not surprising that ASML became more interested in TU/e right around that time, because that was precisely when the company started working on the EUV technology which it would go on to monopolize. That technology required plasmas, says Kroesen. “Which were easy to 'shop for' in the Netherlands. There were only two parties that could help them with that: the FOM Institute for Plasma Physics Rijnhuizen in Nieuwegein, now known as DIFFER, and our group.” Even after Kieft’s doctoral period, there remained plenty of things to investigate in the field of plasma physics for the university. For example, it turned out that the background gas floating around inside the machine used to generate the EUV beam was ionized; that gas also became a plasma. “This opened up a new field of technology, but also plasma physics, that we stepped into. And we’re still working on that today, we are far from finished. The interaction between the beam of radiation in the machine and the background gas and everything else inside the machine: that’s a subject that requires a lot of background knowledge.”

Would you say that Kieft’s initial research yielded nearly twenty-five years of research material?

“Yes, we’ve been building on it for all these years. We’ve now added another new research topic, which is about contamination from small dust particles. As it turns out, the plasmas do crazy things with those particles. The dust becomes electrically charged and is then deposited in places where you don’t want it. That is where our focus currently lies. So what subfield you cooperate in varies and also depends on how far you have already progressed with a subject together. The biggest mistake you can make as a university in a collaboration like this is stubbornly sticking to your own subjects. You need flexibility and understanding for other parties to be able to work on something together.”

But surely you can decide as a university to continue working on a subject independently if you find it interesting enough?

“Yes, of course you can, but then you’re creating a product when there isn’t a customer for it.”

That’s what universities are for though, right?

“Yes, but TU/e is also a technical university that listens to what is needed in society and industry. That also works as a motivator. If you know that your research is relevant to society, that gives a lot of satisfaction. It’s a trade-off that yields good research on both sides. That doesn’t mean we lose sight of our primary goal as an educational institution: which is to educate people. The research we conduct facilitates education. So you can only do research that is publishable - at least in the long-term.”

Does it ever happen that discoveries are made that are not publishable?

“Sometimes you have to decide not to include certain results in a dissertation. It happens quite regularly that some things are not included or are added at a later point in time because a patent has to be filed first. What helps is experience and a good working relationship. If a PhD candidate finds something here that raises intellectual property concerns, we discuss with ASML how this can be protected. Sometimes that involves patenting certain things. Either on their part or on ours. What also happens in some cases is that the university applies for the patent and later sells it to ASML. You have to keep a dialogue about that and make sure that it’s mutually beneficial. It’s not a one-way street, it brings satisfaction to both sides. It’s an ongoing game of translating ASML’s technical needs into sound academic research. That’s something we do together.”

So all this time you have managed to make it work together, how come that relationship is so good?

“You have to be considerate of each other and sometimes go the extra mile when you know something is important to the other party - even if it may not be that important to you. That balance was good right from the beginning. We also spend a lot of time discussing things together. We have collaboration projects where there are biweekly meetings with all the people from ASML and the university who are involved. I often sit in on those myself. When I was dean, I didn’t have as much time, but even then I tried my best to be there. That’s not to say that I’m involved in all the projects; there are so many now that I’ve lost count. I estimate that there are five or six PhD candidates in our group alone who are partly funded by ASML, and on top of that, there are a lot of students completing their graduation or internships there. I do try to keep a general overview and focus more on the strategic part. More TU/e staff members are working on that, but they regularly get me involved.”

Is that because you’ve been around for so long?

“I think so. That also played an important part in bringing about the recent agreement. I can pinpoint exactly when it came about. It started with a meeting organized by Board President Robert-Jan Smits, who had brought together the then head of Research at ASML and other important figures. Among them were also the deans of relevant departments. My role in all this was to make sure we remained on the same page. I know how people think at the company and what they expect from this kind of research.”

What do they expect?

“They are very quick to make the switch between a fundamental scientific concept and a very concrete item in the machine and its production. You have to be able to keep up with that pace. Not everyone at the negotiations had that kind of experience, so I acted as a sort of bridge builder to make sure everyone stayed on the same wavelength. Someone to grease the wheels: an oil man. Ultimately, about four subjects were brought up during that first meeting that ASML was interested in. Those subjects are also included in the agreement. They are: plasma physics, optics, artificial intelligence and mechatronics. I was asked to mediate at times, especially for the subjects of optics and artificial intelligence; not so much for mechatronics, because they have also been working with ASML for a long time.”

As long as Applied Physics has?

“I recently looked up when the first mechatronics PhD collaboration with ASML took place. And we were first (he laughs). But there is certainly a lot of collaboration in that field. Maarten Steinbuch has rightly said that ASML’s wafer stage is the most advanced piece of technology on earth. I believe that’s true. The wafer stage consists of a 30-centimeter slab of silicon, the size of a frying pan. This moves at the speed of several times the gravitational acceleration, in other words, extremely fast, and has to be positioned with nanometer precision. These are very extreme conditions. So it was only natural that ASML also wanted to tap knowledge at mechatronics, the same way they tapped into our plasma knowledge. We also have part-time professors from ASML working at the university in both areas.”

You spent some time at ASML yourself, right?

“That’s right, that was around 2009, for about a year. The Netherlands was in a recession at the time, and so was ASML. That’s when they introduced a kind of knowledge worker scheme: the government would help companies if they stationed people at universities. We jointly submitted several proposals within this scheme, all of which were approved. We’re talking about several millions of euros. Under the arrangement of that subsidy scheme, I became the supervisor of twenty ASML employees. I took that very seriously. I wanted to talk to everyone so I would at least know what everyone was working on and I also just liked being there for one day a week. I would talk to eight different people on such days; they could sign up for that, and it was always fully booked. What I really appreciated from ASML was the fact that, unlike many other companies, they did not cut back on research. They only received a quarter of their normal revenue back then, yet they continued to innovate. Strategically, that was a very good move, but it also greatly motivated me to opt for such a joint program.”

It sounds like many years of very intensive contact with ASML.

“That’s exactly what it is. I met new people all the time but I got along well with everybody. There has been good bilateral contact for years. We also call each other when necessary. Not many people know my phone number, but the key people at ASML do. They know I don’t like being called so they don’t just call for any reason. That accessibility, giving each other time and knowing when to pick up: we’ve had that for about twenty years. We know we can trust each other.”

Does your contribution to the new collaboration make you proud?

“It does make me proud, but not overly so. It’s not all my doing alone. It is something I’ve wanted for a long time though, a structural collaboration like this. I used to dream about a sort of joint technology institute and this is kind of like a version of that. The recent addition of plans for a new clean room feels like icing on the cake. With a physical collaboration and joint facility, you can make progress.”

Will you stay involved in the future?

“I’m no longer a dean and in two years I’ll retire. I don’t particularly want to, but that’s the law. I’m going to contribute as much as I can over the next two years to ensure this collaboration is well established, but I’m also going to hand things over to others. I no longer have a formal role to play myself, nor do I want to get in the way of my successor. I’m going to do this in such a way that when I retire, it will be painless and no one will be inconvenienced. In these sorts of cases, you have to make sure that you don’t leave too emphatic a mark. Things are successful when they are someone’s “baby,” something they feel identified with. I have to make sure those babies can be born into existence, but that others can be the parents.”

Sort of like a midwife?

He laughs: “Yes, something like that.”

Discussion