Perovskite solar cells pass test

New solar cell modules based on the mineral perovskite, packed in glass and prepared with stabilizing layers made at TU/e, are able to withstand fluctuations in moisture, light and temperature. This has now been shown by Solliance, a joint venture between, among others, TNO, innovation hub imec from Belgium and TU/e. This is an important result, because the lifespan of perovskite is still a major concern surrounding this promising new technology.

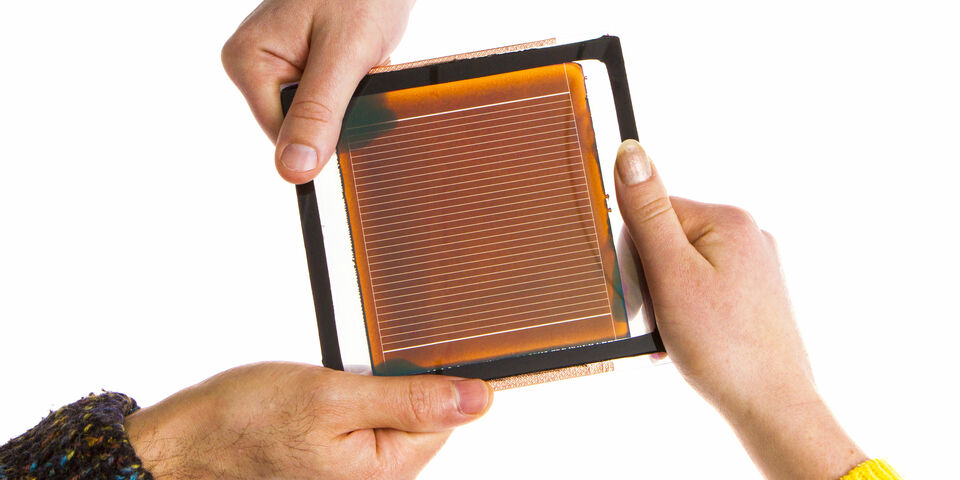

Potentially, perovskite cells combine the advantages of conventional silicon cells (high efficiency) and ‘plastic’ solar cells (inexpensive, thin and flexible). One of the foreseen applications is placing semi-transparent perovskite cells on top of other solar cells, which will make it possible to use a larger part of the solar spectrum. Unfortunately, the lifespan is still a major stumbling block: ten years ago, the first perovskite cells lasted only for a few minutes.

Research into this new technology is being conducted at TU/e, including in the Molecular Materials and Nanosystems group of Spinoza Prize laureate René Janssen, also in collaboration with Solliance. However, a direct contribution to the improved lifespan of the perovskite modules that have now been tested, was made by TU/e professor Adriana Creatore (Plasma & Materials Processing, Applied Physics).

Creatore is an expert in the field of atomic layer deposition, a method for depositing extremely thin layers of a specific material with great precision – for example in a solar cell. It has been shown that such thin layers of metal oxide can increase the stability of perovskite cells. “You can literally think of the metal oxide as a protective layer,” she explains. “But our layers also play a role in the transport of the charge carriers in the solar cell. In our group, we investigate which type of layers are optimally suited for this purpose. We have been working on this with Solliance for five or six years now, and it his already resulted in more than ten publications and a patent. The collaboration is clearly a very fruitful one.”

It’s the size of the tested modules that make the test results particularly special, Creatore explains. “Most research is done on extremely small cells. Solliance has now made fully fledged modules that can easily be scaled up. That is why this step is a milestone in the development of perovskite cells.”

Stability test

Researchers at Solliance have now managed to make 15x15 centimeter modules, says Sjoerd Veenstra of Solliance. For a period of 1000 hours, these were – encapsulated between two glass plates – subjected to three stability tests: exposure to (the equivalent of) direct sunlight, a high humidity level, and temperatures between -40 and +85 degrees Celsius.

These procedures did not lead to any significant reduction of the panel’s initial efficiency of about ten percent. Incidentally, researchers at Solliance’s lab are now able to produce perovskite cells with an efficiency of 21 percent, comparable to the familiar silicon cells, Veenstra emphasizes. “But we haven’t scaled that technology up to modules yet. We do have modules with an efficiency of 15 percent already, but these haven’t been tested yet.” According to Veenstra, no other party has of yet managed to produce such stable perovskite modules. The plan is to also test modules under realistic conditions, outside the lab. The testing facility on Vertigo’s low rise might qualify for this.

Discussion