Home Stretch | Machine for chips with light

In order to make large-scale production of affordable photonic chips possible in the near future, it would seem logical to borrow lithography techniques from the electronics industry. A unique machine from chip-machine manufacturer ASML allowed Jeroen Bolk, as a technician at NanoLab@TU/e, to examine this option in detail. He even gained his PhD recently – online – for his findings.

Jeroen Bolk sat at home behind his laptop at one-thirty in the afternoon on May 12, with an extra laptop within reach and an alternative Wifi connection as backup in case of an emergency. No hall, no podium, no guests, no tailcoat; but nevertheless, here he was, defending his thesis in front of a committee that also sat at home. “Exactly how that online defense would work became clear only one week in advance. Unfortunately, no one could watch the actual defense, but I did post a recording of it on YouTube that very same day and sent a link to the people I normally would have invited.”

Forty-three-year-old Bolk, incidentally, never thought about obtaining his doctorate when he joined NanoLab@TU/e as a technician in 2009. After graduating from the higher laboratory school – specializing in chemistry – he started to work at the NatLab and eventually ended up at NPX, the former semiconductor division of Philips in Nijmegen. But since he didn’t see enough opportunities for innovation there, he decided to make the switch to TU/e. “I had already learned much at that point about how you make electronic computer chips, but I’d never heard of photonic chips,” he admits.

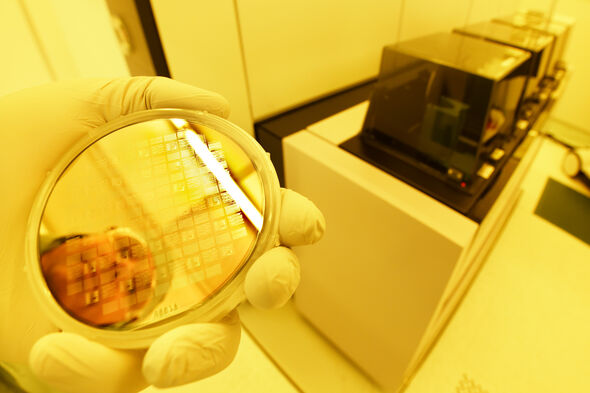

Within the Photonic Integration group (Electrical Engineering), research had had just started into large-scale production of photonic chips – a potentially very fast and energy-efficient technology that uses light to carry information instead of electrons, as in standard computer chips. “Photonic chips were really still in their infancy at that time. In 2010, we received a wafer scanner from ASML, which can be used to accurately make patterns of 100 nanometers. The price of a new machine is ten million euros and it weighs thousands of kilos – we even had the adjust the floor of the lab for it.”

Normally, a wafer scanner works with 'wafers' of silicon with a diameter between twenty and thirty centimeters, while the basic material for photonic chips consists of wafers of indium phosphide of only three to four inches (7.5 to 10 cm). “The machine couldn’t process such small wafers, which is why ASML eventually adjusted the machine in 2012 so that it could handle small wafers as well. That meant we had the only machine in the world with which you could make such accurate patterns on wafers for photonic chips.”

Slide projector

Bolk, in his capacity as technician, spent the following years addressing the question of how you could actually make photonic chips with this unique machine. For that, you need to make extremely small patterns using a technique known as photolithography. “You could irreverently describe ASML’s machine as an expensive slide projector,” he says. The wafer scanner contains an argon fluoride laser that emits ultraviolet light with which a pattern is projected on the wafer via a mask and an advanced lens system. That wafer is fitted with a light-sensitive coating, so that the projected pattern can be etched out at a later stage.

The patterns on photonic chips, incidentally, are fundamentally different from their electronic siblings, Bolk explains. “Angular patterns, for example, don’t pose a problem to electronics, but in order to transmit light you need rounder, smoother structures.” For the eventual photonic chip, ten to twenty of such patterns are applied on top of one another in layers. “This means you need a machine that checks the thickness of the layers, whether the structures have the correct dimensions, and whether they are applied on top of one another in the correct way. You need an entire infrastructure for that, and I was responsible in first instance for the technical support.”

Researcher

In 2017, the technician was asked whether we wanted to continue the project as a PhD candidate. “That scientific work fitted seamlessly with what I had done in the years before, and I thought it would be interesting to take on the role of researcher. In addition, time had already been made available for me to support this setup, although I haven’t completely given up my role as technician in the end.”

In the past years, Bolk proved that the wafer scanner can be of added value for a part of the patterns for optical chips, and that it even creates possibilities for developing photonic building blocks that were inconceivable in the past. In some ways he has come full circle, the brand-new doctor says. “We are now working on photonic chips that can be used as sensors to make the new generation of chip machines even better. I think that’s great.”

Discussion