Completion CASA 1.0 scheduled for the end of June

Antoine Post, master’s student Physics and Electrical Engineering and manager of Team CASA, is to receive the keys of his new home three months from now. By that time, contractor Hurks will have completed its six months construction process of the circular and future-proof home commissioned by housing association Woonbedrijf, of which Post will be one of two tenants. Both Post and Hurks continue to learn much during the construction of CASA 1.0.

Standing on the construction site at the west side of the Helmond neighborhood of Brandevoort, project manager at Hurks Paul Claes talks about the project with a big smile on his face. “Working with this student team is a special experience. You talk to them about a certain adjustment and tell them how important it is to properly document this, and they look at you surprised and say: ‘Yes, but didn’t we already discuss that orally yesterday?’. This way, they learn that things work somewhat differently in daily practice. But we should by no means stop them from putting forward their ideas. That’s inspiring to us too.”

Happy tenant Antoine Post gives Cursor a guide of his future home, of which only the facade is still missing. The detached building borders on cornfields, and no other buildings are to be found in its direct vicinity. The nearly graduated master’s student gives a full lecture on the construction process, the sustainable advantages, and on the circular value of CASA 1.0.

As a first step, a giant pyramid shaped storage tank that holds 130,000 liters of water was buried underground in December of last year. The solar panels and piping system, comparable to a floor heating system, are located on the roof. This system, however, is meant to cool the panels – and, consequently, the roof –, and the heated water that runs through the system is further heated to 75 degrees Celsius with a heat pump and stored in the underground tank. Once the building is completed, it will be possible to generate the power needed to circulate the warm water through the entire building with only a small aquarium pump, Post says. Separate cold water will be pumped during the summer to keep the building cool.

Service core

An important aspect of the building’s construction is the fact that no concrete was used, since this leads to high levels of CO2 emission. That is why CASA 1.0’s foundation consists of a grid of hollow tubes that were driven in the ground several meters apart and subsequently filled with gravel. Other materials used for the building include steel, chipboard, plasterboards and insulation material.

The most important part of CASA 1.0 is the so-called service core. This two-by-two-meter center piece that runs from the building’s top to bottom floor serves as a framework for the entire steel construction and integrates elements such as ventilation, sewerage system, electricity, et cetera. Post says that it remained to be seen whether it was still possible to come up with a proper layout for a home on a total surface of sixty square meters and with such a core at its center. Post: “That definitely proved to be the case; there’s enough space for the living room, the kitchen and the bedroom, and the bathroom can even be accessed from two sides, including directly from the bedroom. What a luxury.”

In time, he hopes that it will be possible to completely separate this part of the building’s construction and to prefabricate it in a production hall, after which it can be added to the building in one piece at a later stage. Post: “That wasn’t possible during this pilot, we really had to build it on the construction site. Because having to add parts to the building’s core afterwards would have been a very difficult and time-consuming job.”

Post also shows Cursor the steel framework on which the different parts are placed in a relatively simple way with nuts and bolts. “Should it become necessary to dismantle this building one day, it will be easy to disassemble that framework and to reuse the steel.” Project manager Paul Claes says that the steel framework’s corners are stamped so as to make sure that everything is fully leveled. “We’ve learned from practice that those stamps really are necessary, but the students feared for a moment that these were permanent. Those stamps will no longer be necessary however once the building is completed,” Claes says with a smile. The places where the steel parts converge were covered with synthetic material. “This was done to make sure that we won’t have any problems with the acoustics,” Claes says. “This, too, is an adjustment that we thought up in collaboration with the students during the construction process.”

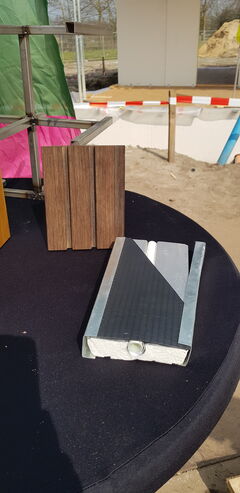

Bamboo facades

The building’s facades will be placed in two weeks’ time, after which work on the finish of the interior commences. “The facades are made of compressed bamboo fibers,” Post says. “Bamboo grows extremely fast, and when you heat and subsequently compress the fibers, you get this very strong material that’s also very weatherproof. These bamboo fibers don’t contain any plastics, unlike the bamboo fibers used for cutlery and other utensils. That material isn’t eco-friendly because it can’t be reused. Our facade slabs, however, can be recycled.”

Thought-out design

The fact that the design was well thought out is also apparent from the details. For example: the collected rainwater will be used, after some filtering, for flushing the toilets. And short horizonal awnings will be placed above the windows. Post: “These awnings prevent sunlight and heat from entering the home during the summer, when the sun gets higher and higher. That means that it remains cooler inside. No luxury, now that our summers are getting increasingly extreme. During the winter, when the sun’s angle is lower, sunlight will enter the rooms more easily.”

Tenants who move in on the ground floor after Post and his girlfriend have left, will have no trouble redecorating. Post: “The walls can be easily taken down and placed elsewhere. There is much flexibility, you don’t need to demolish entire solid walls if you want to redesign.”

Long term

Post and his team felt that the collaboration with a housing association on this project was a great advantage. “These kinds of organizations consider the long term, and they also realize that housing construction is changing. They show great interest in sustainable construction, because they don’t want to have a problem on their hands thirty or forty years from now, should something need to be taken down again. Project developers usually doesn’t care about that. They simply build something, sell it, and don’t need to worry about it any longer,” Post says.

Hannie de Groot of Woonbedrijf is also proud of the project in Brandevoort. “I hope that we can turn the completion at the end of June into a festive occasion, but that naturally depends on how the corona pandemic develops over the next few months.” Post and his girlfriend move into the building’s ground floor apartment in early July, a second tenant will move into the first floor apartment and a third part of the building will be turned into some kind of showroom for Woonbedrijf and Team CASA.

A digital press conference is scheduled for tomorrow, Wednesday April 7, during which Helmond alderwoman Cathalijne Dortmans, general director of Woonbedrijf Ingrid de Boer and Inge Schipper of contractor Hurks will give a brief explanation. After this short introduction, there will be an opportunity for questions. Click here if you wish to participate in the press conference.

Discussion