- Research , Home Stretch

- 17/11/2021

Home Stretch | Plastic in a magnetic bath

What a luxury: all of Amsterdam's collected plastic waste now gets to slip into a cleansing bath. This comes courtesy of recycling company Umincorp, which is passing plastic fragments through a bath filled with a magnetic fluid in order to separate out the various types of plastic. Doctoral candidate Rik Dellaert studied the behavior of the plastic particles in the liquid stream in order to help perfect this new method, which enables the recycling of plastic waste into high grade products.

Every year in the EU alone, more than six million tons of plastic is thrown away. As yet, as little as five percent of this total is recycled. This is partly because this mountain of waste is an accumulation of all types of plastic and the scope for reusing this random mix is limited to relatively simple items such as garden benches and highway location markers. However, if the commonly used plastics polypropylene, polyethylene, polystyrene and polyethylene terephthalate (better known as PET) can be separated out, it becomes possible - and economically interesting - to use them to produce high grade recycled plastic.

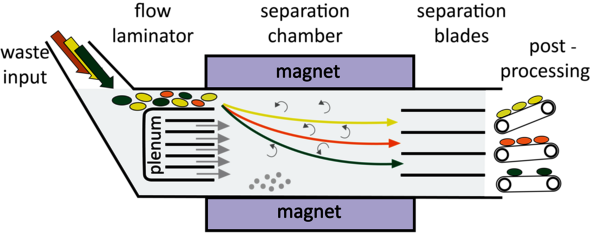

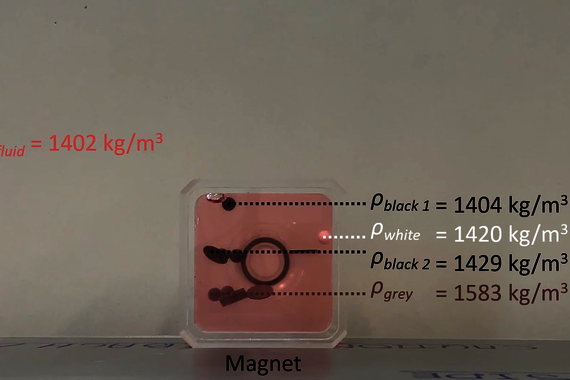

And this separation is exactly what happens in Umincorp's magical magnetic bath, explains Rik Dellaert. The recycling company is employing a unique technique - magnetic density separation - devised at TU Delft. “The plastic particles are guided through a bath of magnetic liquid. The bath stands in a magnetic field, which at its base has a field strength of roughly one tesla.” The magnetic field decreases in strength the higher you go, so that the 'apparent density' of the magnetic liquid is highest at the bottom of the bath.

Centrifuge

“This causes the plastic particles to float at a height consistent with their own density,” explains the doctoral candidate from Zeeuws-Vlaanderen, the southern part of the Dutch province of Zeeland. Since every type of plastic has a different density, it is a simple matter to separate the different types of plastic in their various liquid streams at the bath's outlet (see also the illustration below). “Next, a centrifuge is used to draw the plastic from the magnetic liquid, so that both can be reused.”

Text continues below illustration

Turbulence and collisions

The optimum working of the separation machine is susceptible, however, to two problems: turbulence in the magnetic liquid and collisions between the plastic particles. Dellaert researched both processes in the research group Fluids and Flows at the Applied Physics department. “Naturally, you are aiming to have the plastic move as fast as possible through the machine, but that can cause turbulence, which mixes up the particles again. Similarly, collisions between plastic particles moving upwards or downwards can also slow the separation process.”

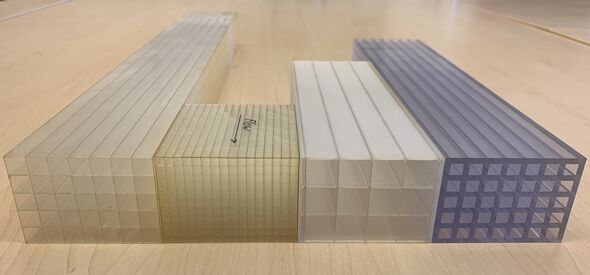

To address the issue of turbulence, he looked at the effect of various laminators, as they are called, through which the magnetic liquid, having passed through the inlet, is guided. “These structures are a bit like elongated honeycombs, and they give the liquid stream its flow profile,” explains Dellaert (see also the photo below). “It turns out that you can produce a peak in the turbulence a couple of centimeters from the laminator, after which this turbulence soon subsides leaving the conditions in the rest of the bath favorable for the separation process.”

Text continues below photo

Mini-wind tunnel

Strikingly, the doctoral candidate carried out these turbulence measurements not in a large bath filled with magnetic liquid, but in a tiny, self-built wind tunnel measuring five by seven centimeters. That's how it works in fluid dynamics, he explains. “You can make very good comparisons between flows at different scales, in both liquids and gases, provided the Reynolds number, as it is known, is the same.”

Mist droplets were blown into the mini-wind tunnel and Dellaert tracked their movements using various laser techniques: laser Doppler velocimetryto measure their speed with precision accuracy and particle image velocimetryto track the movements of numerous droplets in two dimensions simultaneously.

And ultimately, he also conducted experiments in a liquid tunnel, in order to analyze the retarding effect of collisions between plastic particles of different densities. To do this, he used a third technique: particle tracking velocimetry, with which individual particles can be tracked in three dimensions.

Text continues below video

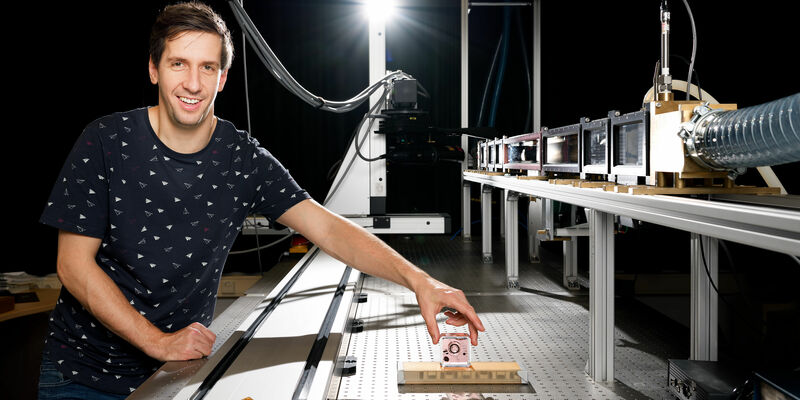

Twenty students

“Particle image velocimetry was something I'd already learned to work with during my first degree in the SMM group at Chemical Engineering and Chemistry; that's what led me to this PhD position,” says Dellaert, explaining his switch from chemistry to physics. Incidentally, for a doctoral candidate he has an unusual academic career behind him: at high school in his home town of Oostburg he started out in the (vmbo) stream that opens the way to secondary vocational education (mbo). “I didn't even excel, my grades were sixes and sevens.” Still, he worked his way up through the mbo in Terneuzen, and higher vocational education (hbo) in Breda (Avans, Chemical Engineering and Chemistry) and in 2016 he achieved his master's at TU/e.

And now he is gaining his doctorate. Partly thanks to his findings - and those of fellow doctoral candidate Sina Tajfirooz at Mechanical Engineering, and others - Umincorp has managed, says Dellaert, to raise the efficiency of the separation technique by a couple of dozen percentage points. “It has all gone perfectly; my thesis is finished and the company really can benefit from the results. And on top of that, I also got to supervise twenty students, which says something about this project's strong appeal.”

Discussion