Rubicon grant for talented TU/e researcher

TU/e materials scientist Tijmen Vermeij, currently working as a postdoc at Swiss Federal Laboratories for Materials Science and Technology (EMPA), will be awarded a Rubicon grant by the Netherlands Organisation for Scientific Research (NWO). This grant will allow Vermeij to conduct research on the steels of the future for 24 months.

The Rubicon grant is intended to give talented young researchers the opportunity to gain international research experience. This experience abroad is often an important stepping stone in the scientific career of a budding researcher.

Every year, NWO gets to fund some 60 young researchers with a total amount of 7 million euros. That amount is divided over three rounds. In the current funding round, NWO will award Rubicon grants to 14 research talents who recently obtained their PhDs.

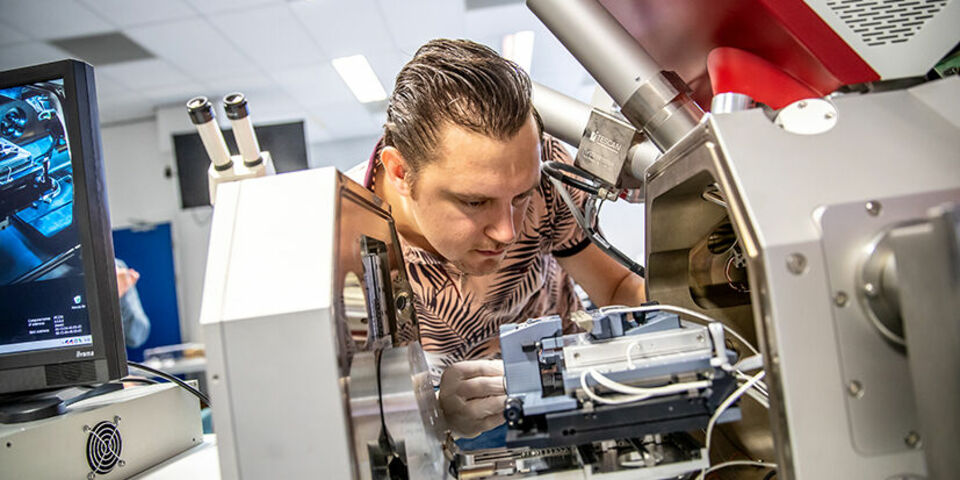

Last year, Vermeij successfully defended his doctoral research with honors at the Department of Mechanical Engineering, where he developed new measurement methods to study the microstructure of advanced steels in great detail. He recently started working as a postdoc at the Swiss top institute EMPA. Thanks to the Rubicon grant, Vermeij will now be able to dive into state-of-the-art research there for the next 24 months, he explains enthusiastically. “My postdoc position was partly funded through industrial sources, but the Rubicon grant has now given me the freedom to really delve into fundamental research.”

Vermeij's research is centered around a complex phase change that occurs in steel. A greater fundamental understanding of this phenomenon could result in improved steels, with new material properties. And that is also important for the industry, Vermeij says. “If we understand what happens in the steel, we can produce steel that is not only extremely strong, but also highly deformable. This would be of great use to the automotive industry; think of a material that can absorb energy in case of a collision, but that can also be easily formed into a car part.”

Discussion