The Road to Valorization | A Matter of Patience

A turbulent summer for HaptonTech

Every year, numerous companies are launched to bring technological innovations developed at TU/e to society: the road to valorization. But what does that road look like? To shed light on this process, Cursor is following spin-off HaptonTech over the course of two years. Part two: patience and flexibility.

It’s the week before the summer holidays when Mert Astam walks out of his workspace in Helix. The CEO of HaptonTech looks tense. We take a walk around campus. “I’m really running on fumes,” he says. His search for new investors has yielded nothing so far. He still hasn’t heard back about the grant applications he submitted months ago. “Without that funding, I can’t hire people,” he says with a deep sigh.

Although he has appointed a former master’s student as Chief Technology Officer and can always call on his scientific advisors for help, he’s still the only one at the helm. That’s starting to take its toll. But despite the stress, he seems just as determined as when he started. “This is the life of a startup founder,” he says matter-of-factly.

Innovation

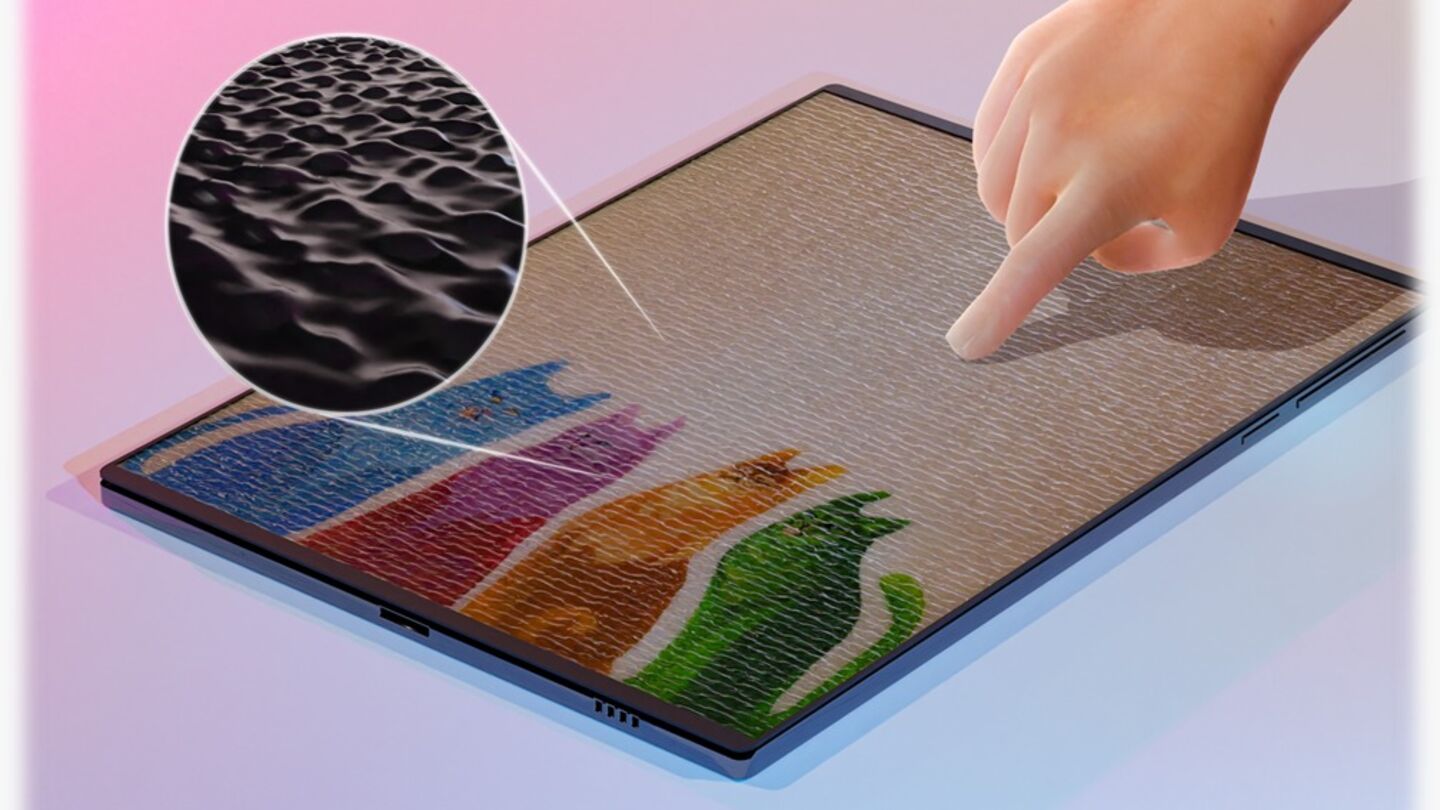

Astam aims to bring to market an innovative material that can physically change shape, providing tactile feedback to the user. Before that can happen, there’s still plenty of fine-tuning to be done, as explained in part one of this series.

Progress on the liquid-crystal-based material itself has been slow. However, improvements have been made to the transparency of its coating — a thin layer of the innovative material — which can be applied in different ways, for example, in phone screens with Braille displays for blind and visually impaired users.

Multiple applications

There is some news to share. A new potential partner has expressed interest in a completely different application of the liquid crystal technology: holograms. The transparent coating can be used to display projections that are visible from only one side — ideal for augmented reality applications, such as smart glasses.

The haptic coating and the hologram technology are two of eight possible applications of the new material for which HaptonTech holds patents. “We have patents covering the optical, mechanical, and haptic functions of the material in various geometric shapes.” Some of these patents will remain confidential until eighteen months after filing.

Exploration phase

Securing eight patents is the result of months of negotiations with the university at the start of Astam’s startup journey. “I wanted as much freedom as possible to test which application works best, since this is a completely new material with multiple potential uses.”

That freedom came at a price. In return, the university demanded the highest possible equity share allowed under the standardized knowledge transfer guidelines introduced in 2023: 25 percent. That percentage will decrease as more investors come on board.

Luck and patience

Less than a month after our walk across campus, Astam’s mood is completely different. He shakes my hand energetically. “We did it,” he says, beaming. “My application for the NWO Take-Off phase 2 grant was approved. We secured €450,000! I can finally hire more people and grow my team.”

To do that, the young entrepreneur wants to bring in TU/e interns. “It’s simply more affordable,” he says bluntly. “But I also have something valuable to offer them. It’s a great opportunity for students to help develop an innovative technology.” He is particularly looking for expertise in tactile displays, optical films, business development, electrical engineering, and software engineering.

Demo

Astam has more good news. Just one day before our latest conversation, he sent his first invoice to Audi. The car manufacturer was already on the radar as a partner, but now they want to see results quickly. Within four weeks, Astam needs to deliver a working demonstration. “They’re sending us a prototype, and we have to integrate our material into it,” he says proudly.

It all sounds a bit vague, but as long as the project is ongoing, Astam can’t share more details due to a non-disclosure agreement. Beyond speed and flexibility, partners also expect a certain level of protection — especially when they are interested in a technology that, for now, exists only in a lab.

Priority

“This could be it,” he continues. “Who knows what will happen. If it goes well, we might land a much bigger project. Then we’d serve one major client as a startup — and that might just become the whole business model! It’s amazing to see how everything can change in just a few weeks. I’m thrilled to be here right now.”

Because of the tight deadline for the demonstration, development of the hologram material has been put on the back burner. Work on haptic displays continues in the background. “But of course, this demonstration is the priority right now.”

Lab space

To create the prototype, Astam says it’s essential to have his own lab and office space on campus — ideally as close as possible to his scientific advisors. Negotiations with the university for his own space are still ongoing, but it’s not moving fast enough for him.

“It’s a bureaucratic process and takes too long, but I need that space now.” Astam is still looking for alternatives and, for now, is working in a shared lab. “It doesn’t really meet the security requirements, but we’ll just have to take that risk until we have our own space. And if I really can’t find anything, I might just have to develop it in my living room.”

Starting your own business not only requires patience, but also constant flexibility.

Series: ‘The Road to Valorization’

In addition to education and research, one of the university’s core tasks is to bring scientific output to society: valorization. Spin-offs play a key role in that process. In ‘The Road to Valorization,’ Cursor is following HaptonTech for two years. In three months, we’ll check in again to see how Astam is doing with his team expansion, the Audi project, and the technology’s development.

Discussion