First year student presents his self-made innovative printer

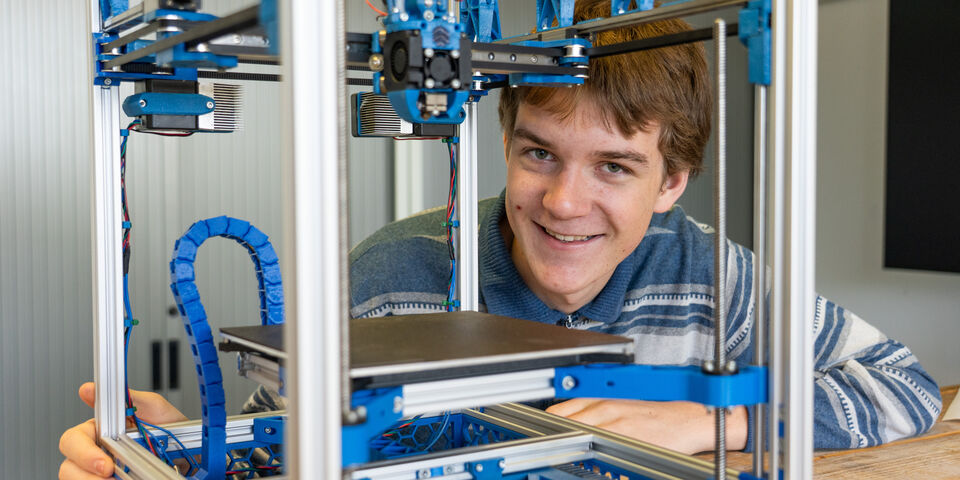

When Tomas Horáček walks into Cursor's editorial room, he immediately draws all attention. The 18-year-old TU/e student Mechanical Engineering is carrying a remarkable, self-built 3D printer. In the morning, he boarded the train in Tilburg with it, and he is eager to explain Cursor why.

“I just spoke with Studium Generale. They invited students to submit ideas for a Student Take Over in collaboration with the Parktheater Eindhoven. I thought it would be fun to work with artists and show my 3D printer to a large audience. But I understand that it’s not easy. My printer is small, and the stage is quite large.”

The good news is that Studium Generale referred Horáček to Cursor, just a door away in Auditorium. We are also eager to hear how he envisions a 3D print performance.

“I already have two ideas. When the printer moves, it makes sound. The pitch changes with the speed. We could program it so that the movement creates music.” His second idea is to add colored lights, creating a light show that can be projected onto a screen. “Combined with the ‘printed’ music, it will become something very artistic,” he thinks.

Magic

But why did he build this special printer? “Let me start at the beginning. When I was ten, I received a 3D printer as a gift. It felt like magic! Creating products out of nowhere fascinated me. That fascination grew, and by the age of fifteen, I decided to build a 3D printer completely on my own.”

He became so absorbed in the project that his father eventually made him pause it, to focus on his secondary school studies in Wallonia. He looks back on it with a smile, because he has now built an impressive printer that he can proudly show to an audience. Whether that will be on the stage of the Parktheater though, is still uncertain.

“My main goal is to present the printer to as much people possible to speed up its development and make it even better. I am indeed looking for a stage for my 3D printer at the Parktheater, but the bigger goal of that plan is to get people interested.”

The unique thing is that Horáček is a first year student. There are many projects that are equally great and even more exciting than this one, but the fact that the inventor in question started it even before entering the TU/e, makes it remarkable.

Four printheads

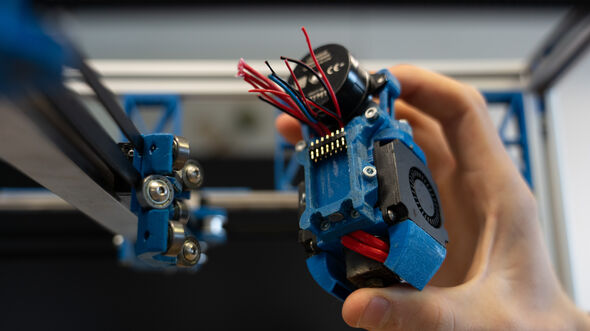

He named his machine Sculptura T1. What makes it special is that it can switch toolheads. The T in the name stands for Toolchanger, and the 1 refers to the first version.

“The machine will be able to attach four different types of toolheads. The first is a 3D printer for printing objects with filament. The second can laser-cut and engrave wooden sheets.” The student does not compromise on safety, planning to install orange plexiglass panels on all sides, to prevent eye damage while using the laser.

“With the third toolhead, you can penplot – that is, draw lines on three-dimensional objects,” he continues. Horáček shows a Billie cup with a QR code that has been penplotted. The last application he has in mind is using a rotating blade that can cut foam or stickers, materials that are too flammable for laser cutting.

“These toolheads can then be configured according to the user needs. It could for example be four 3D printing toolheads which would enable multi-color and multi-material printing.”

“What’s special about my printer is that the different printheads connect to the carrier with a single click [See photo above]. This way, only one set of power cables is needed. Each head requires fourteen cables; multiply that by four, and it would become a tangle.” That connection is essentially the key feature of his next-generation printer. As long as designers use that connection, many more toolheads will be possible.

Printer for innovation

The printer is not fully finished yet, but once it is, it will delight many students and designers. “For clients who need several devices to make their product, one Sculptura is cheaper than a full workshop. It also takes up less space.” Such a customized machine is especially suited for startups, he thinks. A Sculptura T2 might be larger, allowing bigger objects to be made.

But that is still in the future. Horáček first needs to plan his next steps. He wants to learn more about opportunities through an Honors Academy project, but let’s not forget that he is only in his first quarter at TU/e. He is yet to introduce the Sculptura T1 to his mechanical engineering professors.

Still, he would rather start a student team today than tomorrow. “If there are students who want to join the adventure they can email me. I expect my background in mechanical engineering will soon benefit from collaboration with computer science students.” For the record, he adds: “The project will continue regardless.”

Discussion