SOLID unveils new prototype for hydrogen storage

Student team SOLID unveiled its latest prototype, SIR2, on Thursday at the High Tech Campus in Eindhoven. This technology, which uses iron to store hydrogen, can help heavy industries move away from natural gas and take a significant step forward in the energy transition.

“With the SOLID Event 2025, we want to highlight the entire hydrogen ecosystem and showcase our contribution to it,” says Mick Gast, team manager of SOLID. “We’re innovating in hydrogen storage and transport, but we’re just one link in the value chain. Collaboration with other partners is essential to truly make an impact.”

Iron as a storage medium

Hydrogen plays a crucial role in the energy transition, but storing it is complex: the gas takes up a lot of space and high-pressure storage carries risks. That’s why SOLID is focusing on iron as a storage medium. In the so-called Iron-based Hydrogen Storage (IRHYS) process, rust (iron oxide) reacts with hydrogen, turning the rust into iron and releasing water. This allows hydrogen energy to be safely and compactly stored in small iron pellets.

“Iron is an inexpensive, stable and safe storage medium that allows you to store energy for extended periods or transport it to where it's needed,” Gast explains. When the iron pellets are exposed to steam, hydrogen is released and can be used as an energy source in industrial processes. The resulting rust can then be reused by reacting it with hydrogen again, making the process fully circular.

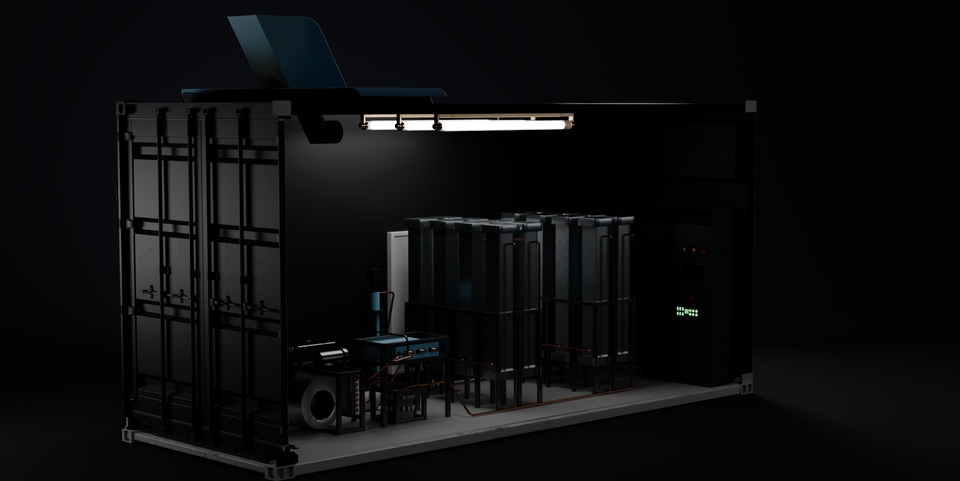

The event featured a keynote and a panel discussion exploring major challenges and developments in hydrogen technology. The highlight was the festive unveiling of the new prototype design: the Steam Iron Reactor 2 (SIR2). It is the successor to SIR1, the first proof of concept launched by SOLID two years ago. SIR1 was able to release one kilogram of hydrogen by reacting iron with steam. “That allowed us to prove, on a small scale, that the technology works,” says Gast.

The new prototype has been scaled up and technically improved, offering greater efficiency, capacity, and power. “This is really becoming a pilot project for industry,” Gast emphasizes. “After construction, we want to test the reactor in various industrial settings to see how it performs at scale.”

Milestone

Although the design has already been presented to the world, the prototype itself is still under development. “We’ll start building in September, and we hope to complete it by 2027,” says Gast. “This is a major milestone for us: from concept to design, and soon to realization.”

While several parties around the world are working on similar technologies, an industrial pilot like this is unique, Gast emphasizes. With the new prototype, they hope to take an important step toward applying this storage method. Their ultimate goal? “We want to help heavy industries — such as glass and steel production — move away from natural gas and become more sustainable,” he concludes.

Discussion